- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

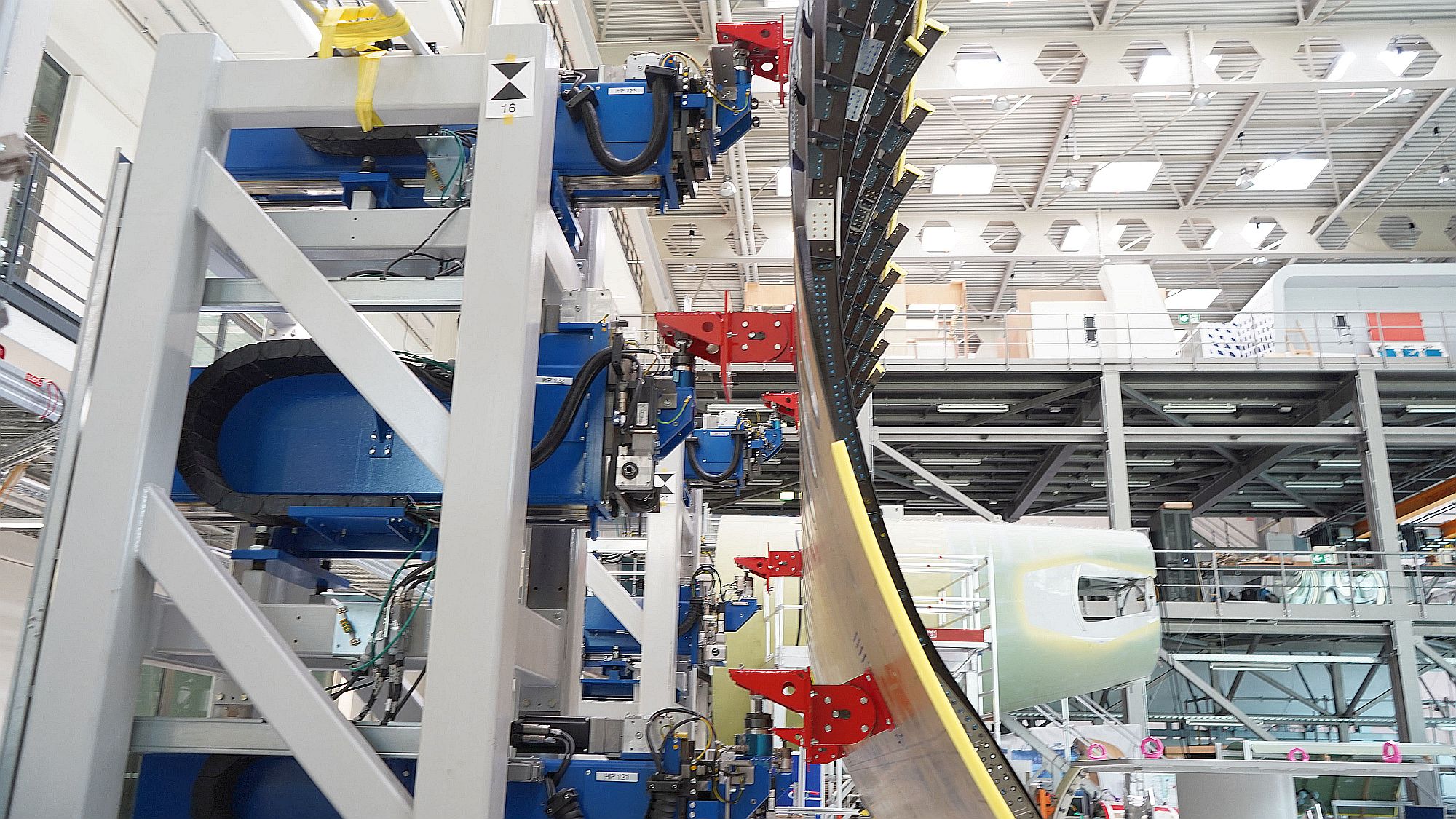

The assembly of aircraft structures requires the joining of large and heavy components with the highest precision. In addition, components, some of which are subject to very tight tolerances, must be joined in such a way that the induced forces on the product are minimized.

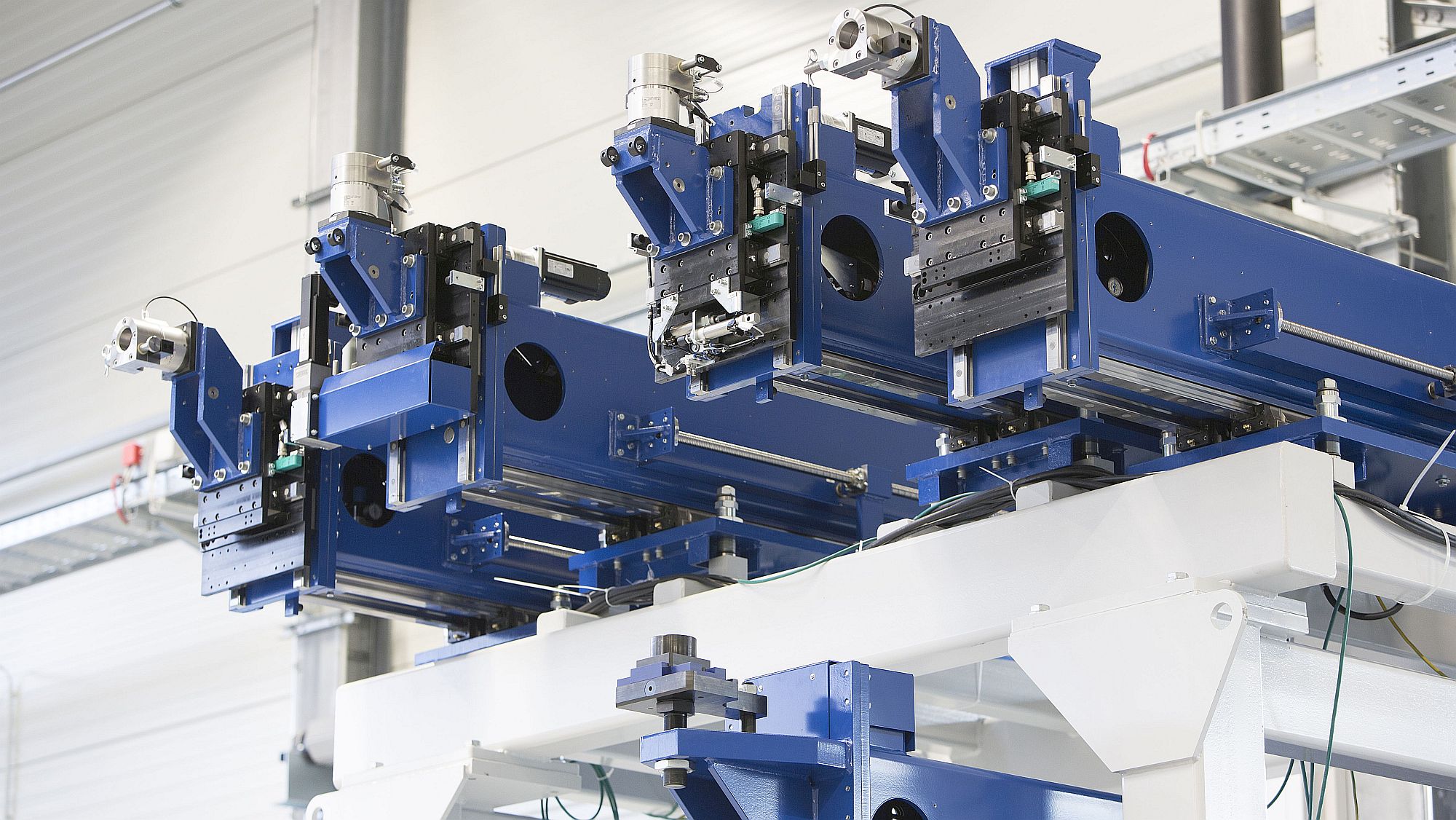

The EcoPositioner from Broetje-Automation, follows a concept for modular and configurable positioning technology that ensures the highest flexibility and product quality for aircraft structure assembly.

To combine highest quality with an easy-to-use system, Broetje-Automation has developed a fully integrated modular control system. This integrates the measuring system with the central data processing and NC drive controls. Everything is controlled from a central control panel with a state-of-the-art graphical man-machine interface.

The positioning system can be used for various types of structural assembly applications; for example, assembling fuselage sections or joining wings and tails to the fuselage. Based on the two product lines – the horizontal and the vertical EcoPositioner line – and due to Broetje-Automation’s modular strategy, more than 100 000 configurations of positioners can be realized. A solution can be offered for every specific process task.

Technical Data

Horizontal

- Positioning accuracy per axis: +/- 0,1 mm (single positioner)

- Repeatability per axis: +/- 0,025 mm (single positioner)

- Stroke, horizontal, long axis: up to 1200 mm

- Stroke, vertical: +/-50 mm min., customizable

- Stroke, horizontal, short axis: +/-50 mm min., customizable

- Speed range: 0,2 mm/s – 20 mm/s

- Payload, vertical: up to 30 kN

- Process load horizontal: up to 2 kN

Vertical

- Positioning accuracy: +/- 0,1 mm

- Repeatability: +/- 0,025 mm

- Stroke, vertical: up to 1000 mm

- Stroke, in flight direction: +/-50 mm

- Stroke, vertical to flight direction: +/-50 mm

- Speed range: 0,2 mm/s – 10 mms

- Payload (vertical): up to 80kN

- Process Load (horizontal) up to 4kN

Product Benefits

Reduction of cost per unit

Automation reduces the scope of manual application. Labour costs decrease, quality assur–ance is greatly simplified. The automated process is faster, therefore the production time is lessened.

Maximum quality

Broetje EcoPositioner technology in conjunction with automated metrology, real time force control and smart data processing guarantees an accurate, reproducible and safe process for consistently superior production quality.

Highest flexibility

The EcoPositioner technology allows the flexible use of assembly stations. Thus the Assembly of several aircraft versions on one station is possible.

The modular concept also provides adaptability of already installed positioners.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.

Innovative Large Mobile Robot for Pioneering Research

- Published on 22 January 2024

- Assembly

- Digitalization

- Factory of the Future

- Mobile Systems

A Highly Flexible Industrial Robot System Opens New Possibilities for the Assembly of the Future at the WZL of the RWTH Aachen. Broetje-Automation delivered the large mobile robot system now to the WZL facility in Aachen, Germany.