- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

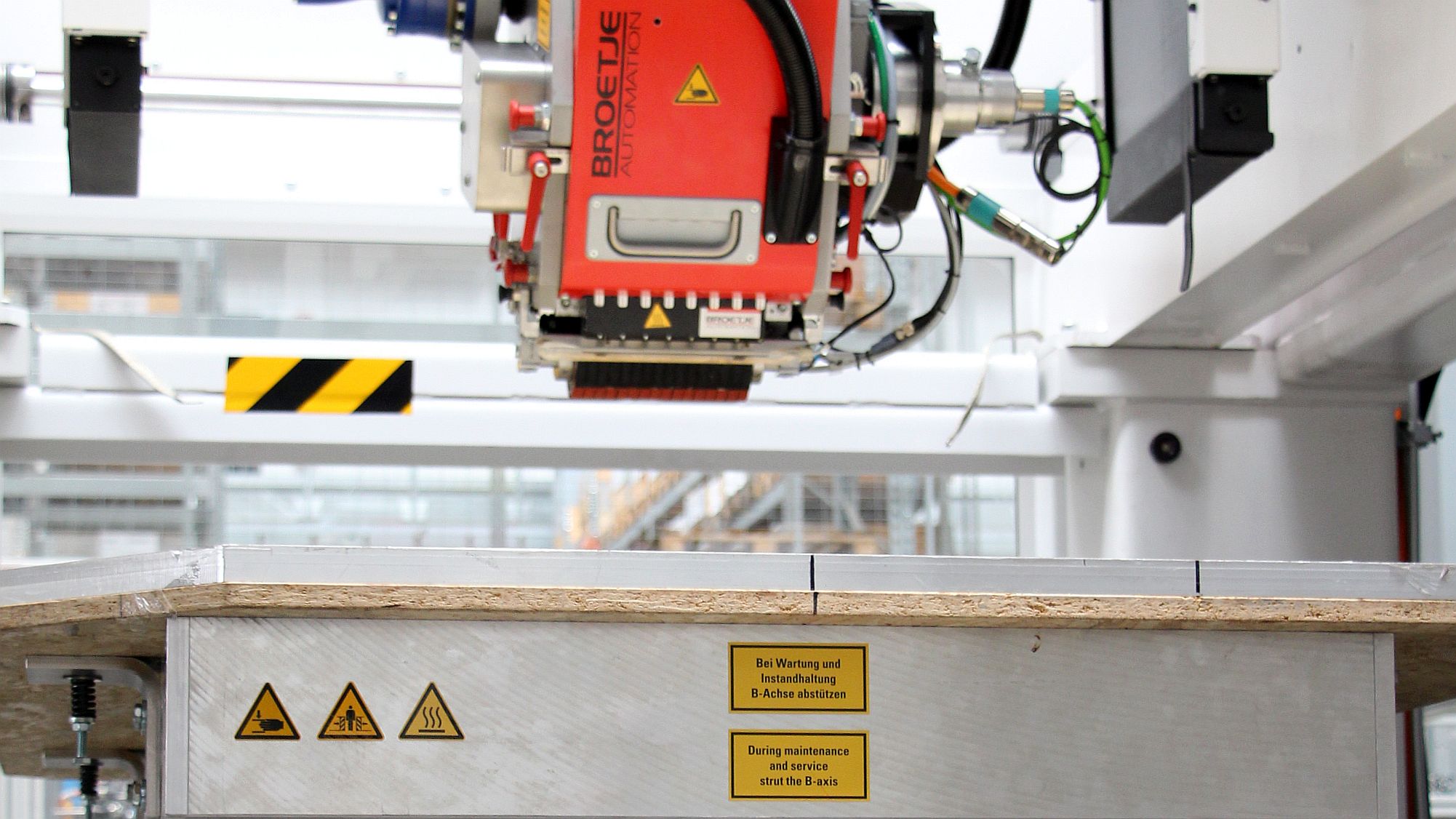

The STAXX 3D offers various options for high-volume production. The swiveling rotary table offers even more possibilities to produce small individual composite parts such as ribs, flat plates, structural parts and tailored blanks. This system is not only highly flexible, but achieves high part quality in a time-saving manner. Designed for a cost-efficient and sustainable production it is ideal for the automotive and aerospace industry.

Technical Data

- 16 tow AFP Head ¼” or ½”

- Layup area max. diagonal 2500 mm

- 6-axis (x, y, z, a, b, c)

- Tilting, rotary table

- Feed rate 60 m/min

- Cut on the fly with 45 m/min

- Direct layup of unidirectional carbon fiber

- Totally enclosed and air conditioned system

- Integrated pallet handling system

- Siemens 840 D SL Control

- High volume production

Cooperation between the Emden/Leer University of Applied Sciences, the Economic Development Department of the City of Emden and Broetje-Automation: regional strengthening through collaboration.

Broetje-Automation, the City of Emden’s Economic Development Agency and Emden/Leer University of Applied Sciences are embarking on a cooperative path from 22.04.2024 to develop and implement innovative solutions to future challenges in the field of sustainability. This will be driven by the “Sustainable Product Development in Mechanical Engineering” course, which has been offered at Emden/Leer University of Applied Sciences since last year.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.