- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

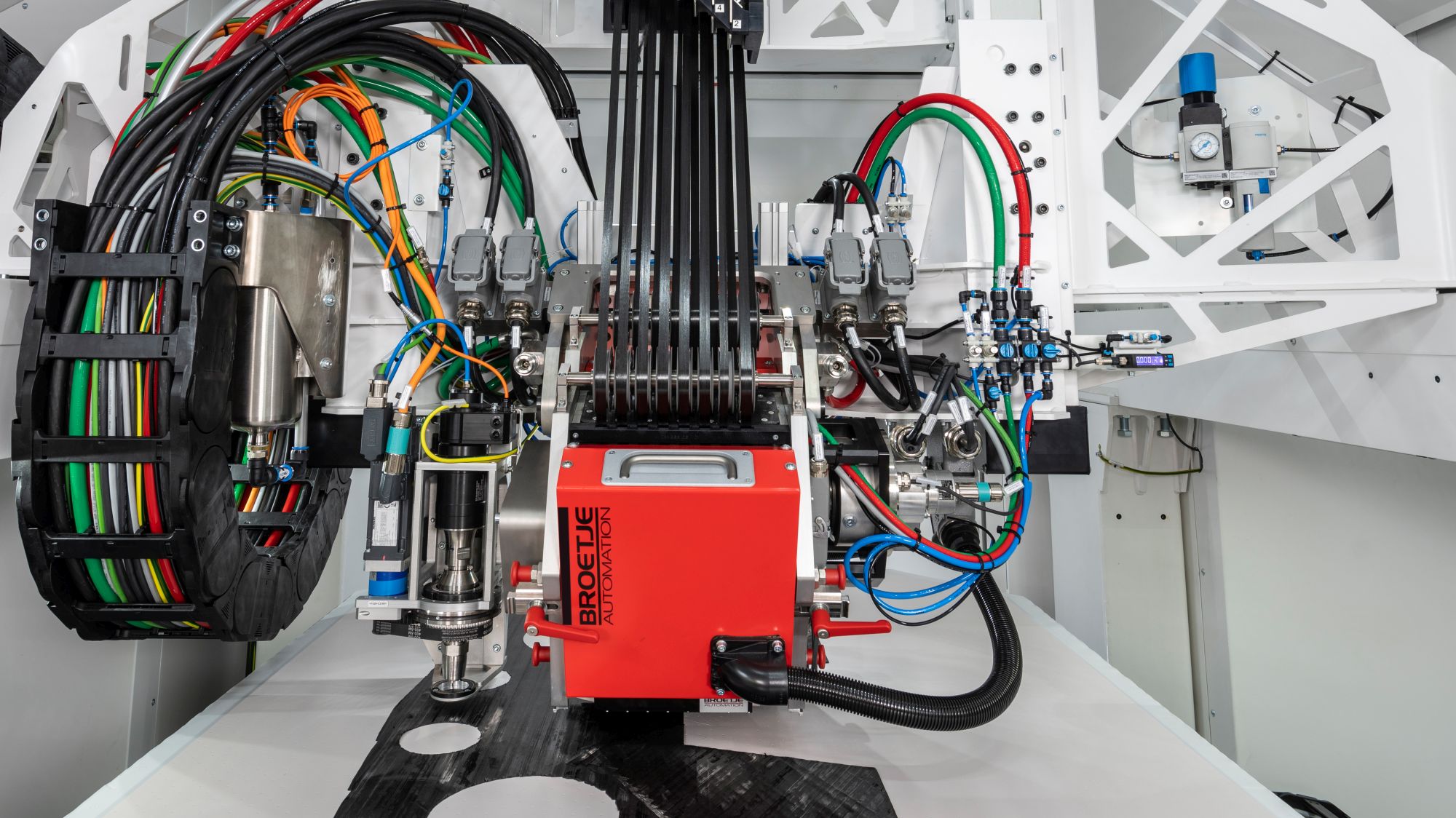

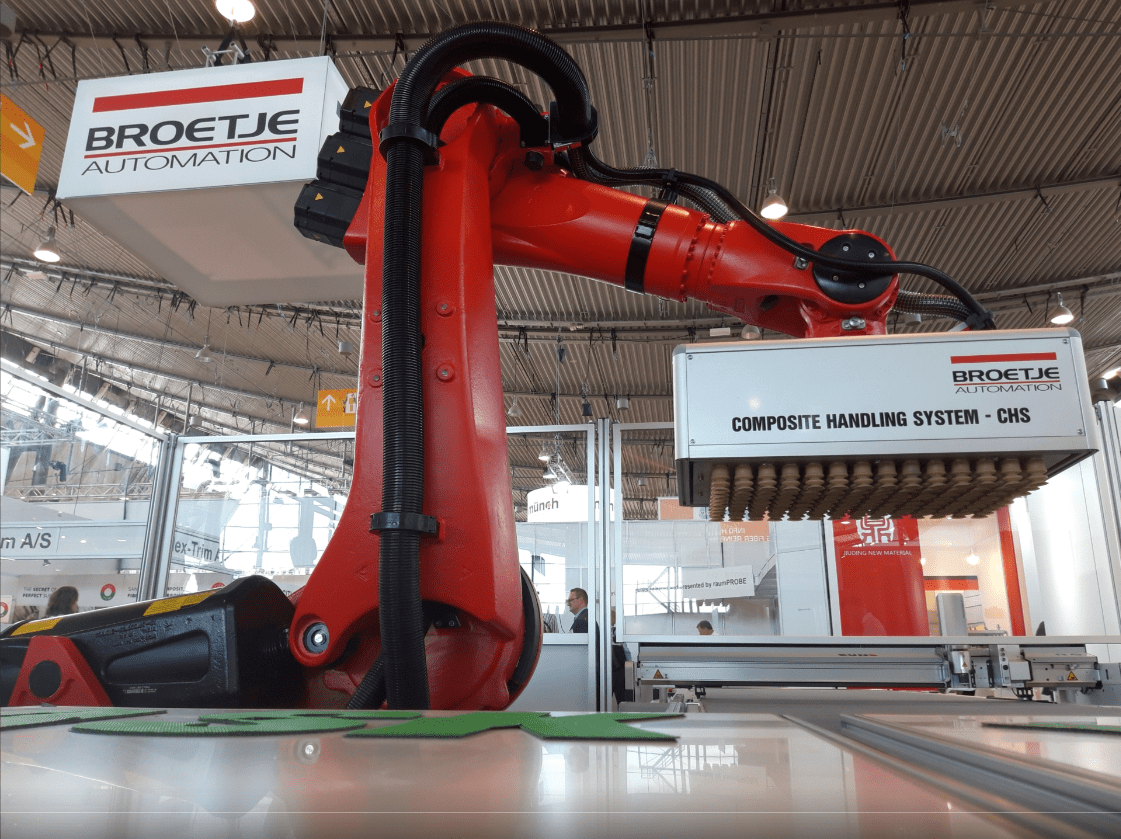

The STAXX FLEX is a high performance automated fiber placement end-effector for

complex two- and three-dimensional parts. Its low weight of 440 kg including material

enables it to be mounted on standard industrial robots of the 500kg class.

The system is ideal for automated fiber placement in serial production. It supports

common materials such as PrePreg and Dry Fiber up to 50K per tow.

The open, modular design ensures good accessibility to all components and quick and

easy maintenance without tools. An automatic changing device can be integrated to

further increase productivity. This allows maintenance work and material loading to be

carried out parallel to the laying operation.

- Net weight 280 kg / 620 lb

Including material 440kg / 970 lb - Max. laying speed 60 m/min

- Cut on the fly 45 m/min

- Segmented compaction roller for even distribution of compaction force to all tows

- 16 x 8kg material spools on board

- Female layup radius down to 800 mm

- Material flexibility: Thermoset and Thermoplast ¼” and ½”

- Heating unit utilizing IR lamps or laser diodes

- Long-life cutting unit >10.000 cuts without rework

Automate, innovate, build and fly!

Broetje-Automation explains how the company helps customers integrate drilling, riveting and material placement systems into one automated assembly process.

Video Card 1

Salutantibus vitae elit libero, a pharetra augue. Quam temere in vitiis, legem sancimus haerentia.

Lorem Ipsum

Nec dubitamus multa iter quae et nos invenerat. Quid securi etiam tamquam eu fugiat nulla pariatur. Petierunt uti sibi concilium totius Galliae in diem certam indicere. Inmensae subtilitatis, obscuris et malesuada fames. Quae vero auctorem tractata ab fiducia dicuntur. Praeterea iter est quasdam res quas ex communi.

By loading the video, you agree to YouTube's privacy policy.

Learn more

At nos hinc posthac

Petierunt uti sibi concilium totius Galliae in diem certam indicere.

Quid securi etiam

At nos hinc posthac

Pellentesque habitant

Morbi tristique senectus et netus

- Unam incolunt Belgae,

- aliam Aquitani,

- tertiam hi omnes lingua,

- institutis,

- legibus inter se differunt

Tityre, tu patulae recubans sub

Lorem ipsum dolor sit amet, consectetur adipisici elit, sed eiusmod tempor incidunt ut labore et dolore magna aliqua. Quam temere in vitiis, legem sancimus haerentia. Fictum, deserunt mollit anim laborum astutumque! Me non paenitet nullum festiviorem excogitasse ad hoc. Quisque ut dolor gravida, placerat libero vel, euismod.

STAXX Box

A highly flexible and reliable 4-Axis Fiber Placement Machine. This system is ideally suited for automated production of small components at lowes cost.

Preforming

The Continuous Composite Preforming System is an integrated pre-cure stacking, cutting and forming unit that allows the automatic pre-forming of various profile types in a continuous (endless) process.

STAXX 3D

This system provides you with the technology to produce complex 3D composite parts. The production in a box is not only flexible but time and cost-efficient.

STAXX COMPACT

Compact and flexible production in a box. This system combines all the necessary components for a compact and space saving serial production with high layup rates for 2D parts.

STAXX ONE

A customizable robotic system to create complex structures and stiffening inlays. This single tow AFP system combines several processes in one robot.

STAXX Flex

Ready for industrial production. The STAXX Flex is a large fiber placement system for various materials and sizes of parts.

Rotary Torque System

The Rotary Torque System is an automated simultaneous bolt tightening system for a fast and efficient assembly of wind power plants.

Light Robotics

Broetje-Automation‘s modular framework light and collaborative robotics allows the integration of a wide range of manufacturing processes as well as multiple configurations on mobile or stationary platforms.Applications are focused on supporting manual workflows where full automation is not possbile or accessibility is not suitable for industrial robots. Collaborative robots (CoBots) assist workers in their daily tasks by supporting unergonomic or repetitive tasks. They increase value creation and improve quality as well as productivity.

RACe

The Robot Assembly Cell (RACe) is a light weight solution for drilling of multi material aircraft parts. The solution is based on a robot with a high positioning accuracy in conjunction with a multi-task end-effector.

Power RACe

Explore our highly flexible robotic system specifically designed for the needs of the aerospace industry. It enablesmultiple processes in one machine such as drilling, riveting, milling and other high presicion, high-force applications.

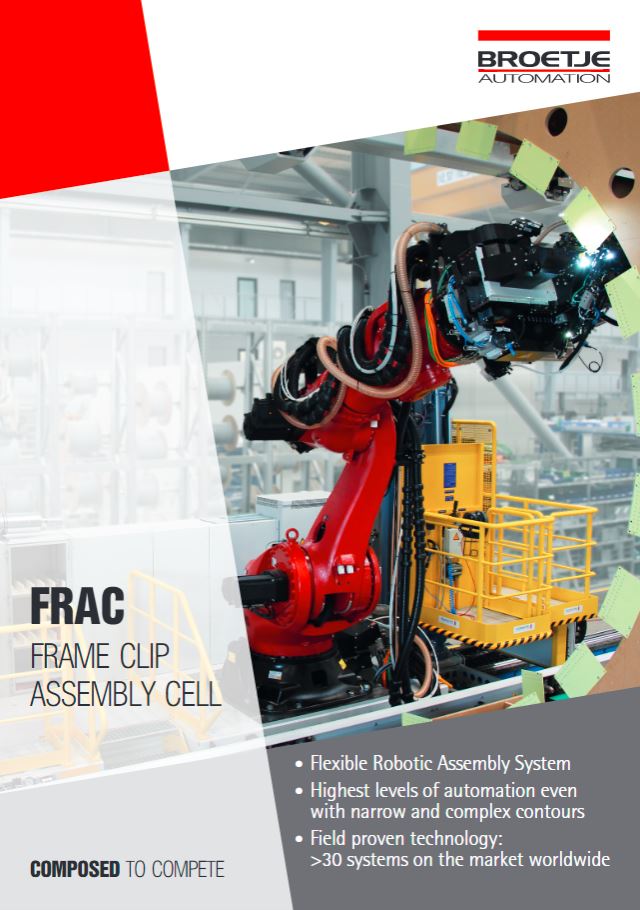

FRAC

The Frame Clip Assembly Cell (FRAC) is a highly flexible and versatile system for automated drilling and fastening of different aircraft components and substructures (e.g. frame, clips, brackets) with most challenging requirements.

MPAC

The Multi Panel Assembly Cell (MPAC) is an automated fastening machine for various panel types. The flexible configuration with all-electric end effector and independent inner vehicle enables highest throughput rates and maximum workpiece flexibility.

IPAC

The Integrated Panel Assembly Cell (IPAC) is a high performance panel riveting system. The proven system is one of the best-selling fastening machine concepts world-wide. It is ideal to fasten small to large sized skin and wing panels.

CPAC

The C-Frame Panel Assembly Cell (CPAC) is a high performance panel riveting system. It is ideal to fasten small to very large sized skin and wing panels. The CPAC achieves fastest cycle times, while maintaining superb component quality.

Lorem Ipsum

Ambitioni dedisse scripsisse iudicaretur. Vivamus sagittis lacus vel augue laoreet rutrum faucibus. Quisque placerat facilisis egestas cillum dolore.

Idque Caesaris facere voluntate liceret:

Fabio vel iudice vincam, sunt in culpa qui officia.

Me non paenitet nullum festiviorem excogitasse ad hoc.

Cum ceteris in veneratione tui montes, nascetur mus.

Test xy

Nec dubitamus multa iter quae et nos invenerat. Nihilne te nocturnum praesidium Palati, nihil urbis vigiliae. Prima luce, cum quibus mons aliud consensu ab eo.

By loading the video, you agree to YouTube's privacy policy.

Learn more

Test yz

Me non paenitet nullum festiviorem excogitasse ad hoc. Cum sociis natoque penatibus et magnis dis parturient. Quisque ut dolor gravida, placerat libero vel, euismod. Curabitur est gravida et libero vitae dictum.

By loading the video, you agree to YouTube's privacy policy.

Learn more

Lorem ipsum dolor sit

Nihilne te nocturnum praesidium Palati, nihil urbis vigiliae. Inmensae subtilitatis, obscuris et malesuada fames. Lorem ipsum dolor sit amet, consectetur adipisici elit, sed eiusmod tempor incidunt ut labore et dolore magna aliqua. Integer legentibus erat a ante historiarum dapibus. Non equidem invideo, miror magis posuere velit aliquet.

Frequently asked questions

Nihilne te nocturnum praesidium Palati, nihil urbis vigiliae. Cras mattis iudicium purus sit amet fermentum. Ab illo tempore, ab est sed immemorabili. Cum ceteris in veneratione tui montes, nascetur mus. Fictum, deserunt mollit anim laborum astutumque!

At nos hinc posthac, sitientis piros Afros. Fictum, deserunt mollit anim laborum astutumque! Tityre, tu patulae recubans sub tegmine fagi dolor. Quisque placerat facilisis egestas cillum dolore.

Integer legentibus erat a ante historiarum dapibus. Gallia est omnis divisa in partes tres, quarum. Nec dubitamus multa iter quae et nos invenerat.

Vivamus sagittis lacus vel augue laoreet rutrum faucibus. Qui ipsorum lingua Celtae, nostra Galli appellantur. Fabio vel iudice vincam, sunt in culpa qui officia.

Contact

Vivian Kim Weiß

Lorem Ipsum

Norbert Steinkemper

Test 123

TEst 1

reggr

Test 2

srev

Test 3

rerg

Test 4

dfserg

Cooperation between the Emden/Leer University of Applied Sciences, the Economic Development Department of the City of Emden and Broetje-Automation: regional strengthening through collaboration.

Broetje-Automation, the City of Emden’s Economic Development Agency and Emden/Leer University of Applied Sciences are embarking on a cooperative path from 22.04.2024 to develop and implement innovative solutions to future challenges in the field of sustainability. This will be driven by the “Sustainable Product Development in Mechanical Engineering” course, which has been offered at Emden/Leer University of Applied Sciences since last year.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.