- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

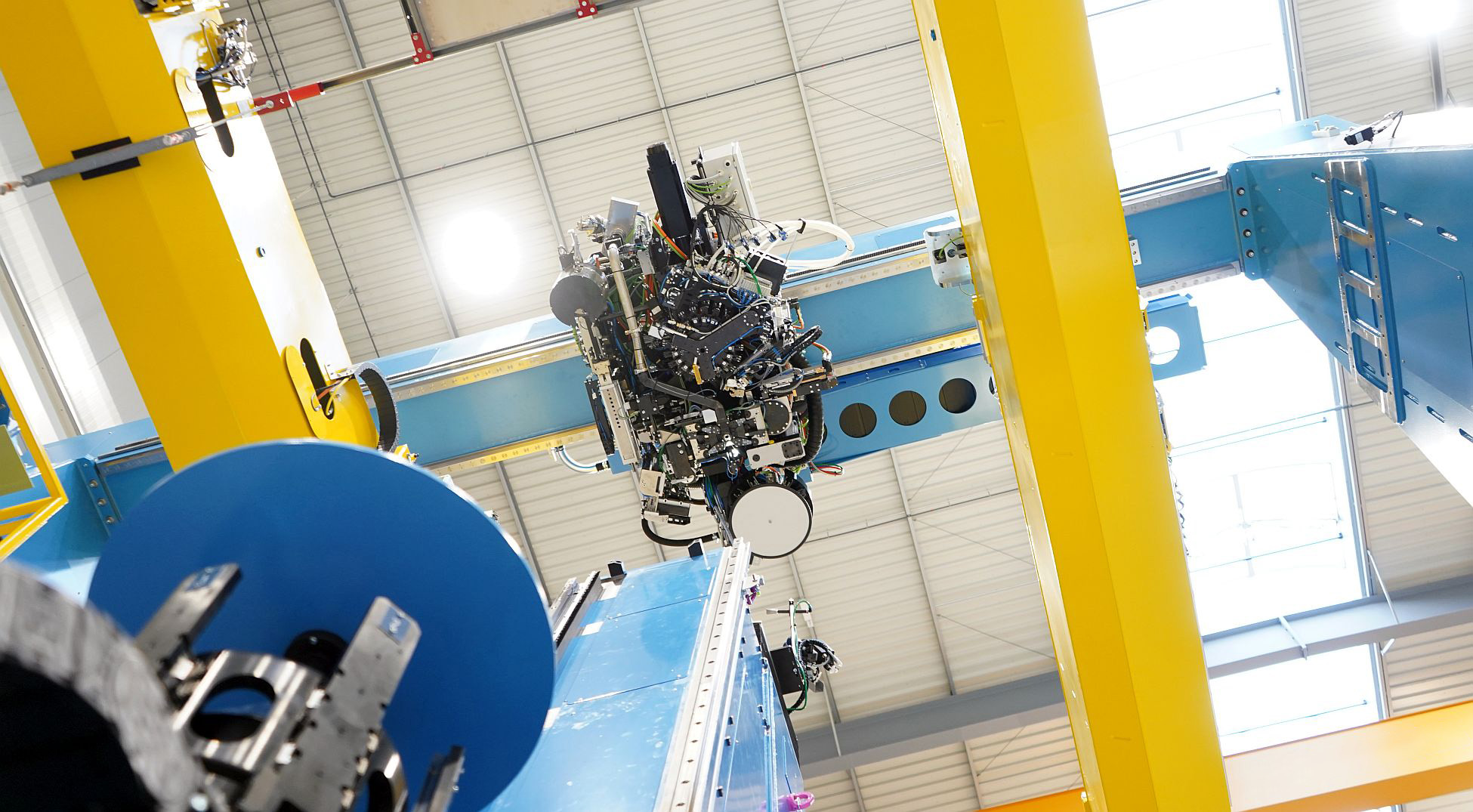

The Integrated Panel Assembly Cell (IPAC) is a high performance panel riveting system. The proven system is one of the best-selling fastening machine concepts world-wide. It is ideal to fasten small to large sized skin and wing panels.

The IPAC achieves fastest cycle times, while maintaining superb component quality. The highly adaptable system can be configured with a flexible fixture tooling to allow high workpiece flexibility as well as easy production process integration.

The IPAC´s compact design and adjustable station layout enables efficient use of precious shop floor space while keeping investment in building infrastructure to a minimum. The workpiece can be loaded vertically as well as horizontally. With more than 50 installations world-wide the system is well proven in production.

Technical Data

Riveter

- Capacity: up to 21ea rivets/min

- Drill speed: 50 – 18,000 rpm

- Countersink repeatability: ± 0.0006” (± 0.015 mm)

- Fastener diameter: 4/32“ – 8/32“ (3.2 mm – 6.4 mm)

- Clamping force: 110 – 600 lbs (50 – 267 daN)

- Drill spindle feed: up to 300“/min (7,620 mm/min)

- Material: Aluminum / Titanium / Composite

- Optional 10/32“ (7.9 mm)

- Upset force: up to 18,000 lbs (8,000 daN)

Positioning System

- linear axes X, Y, Z Positioning accuracy linear axis ± 0.2 mm

- Rotary axes A, B C Positioning accuracy rotary axis ± 60 arc. sec.

Special Features

- All electric fastening system

- High speed tool changer for drill chuck and upper anvils

- High speed / precise drill spindle

- Sensoric system for: Distance, Normality, Tack-rivet and Edge detection,

Countersink Depth, Fastener Head Height, Hole Diameter, Sealant - Automated fastener feeding system

- Ergonomic Offline Programming System (SOUL OLPS) incl. Virtual Twin Integration, Simulation and Production Optimization Tools

- Integrated state-of-the-art Human Machine Interface (SCORE) incl. 3D workpiece completion reports

- Optional slug fasteners

- Optional collar installation

- Optional automatic lower tool changer

IPAC Product Information

Want to know more about our product? Click the Button below to download this document.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.