- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

The fourth industrial revolution for the textile industry

The textile industry was one of the early adopters of automation. As early as during the first industrial revolution, especially weaving machines have been at the forefront of industrialization with a hugh impact on how we live and work until today.

While many of the necessary processes in the textile industry have largely been automated, especially spinning, weaving, cutting and sewing, there are only few integrated systems that interconnect the individual value creation steps.

With our longstanding experience with process integration within complex environments, we at Broetje-Automation have made it our goal to bring the fourth industrial revolution to the textile industry with an integrated approach.

We are working with a wide range of partners around the world to contribute to greater industrialization in the textile industry and a return to more local production chains. The focus here is on the interlinking of individual production steps combined with consistent, high quality processing.

Non-Woven Fabrics

Business as usual for PPE products means production by labor intensive processes, mainly in the Asian region plus a major carbon footprint.

Broetje-Automation and STARK Medical share the vision of an integrated production system for non-woven fabrics in order to produce medical gowns with a fully automated concept. This will enable local supply chains, and contribute to the stability of supplying critical goods for the medical sector.

Local automated production will result in a highly efficient supply chain, vendor diversification, competitive price and will minimize any current or new geopolitical disruption.

In addition, a recycling program resulting in material reutilization will significantly reduce the environmental footprint.

Woven Fabrics

Todays’ clothing industry is facing challenges due to instable supply chains and questionable working conditions.

Last but not least, this became evident during the COVID pandemic. The support of domestic industry in the production of protective masks laid the foundation for the development of automated technologies for processing textiles at Broetje-Automation.

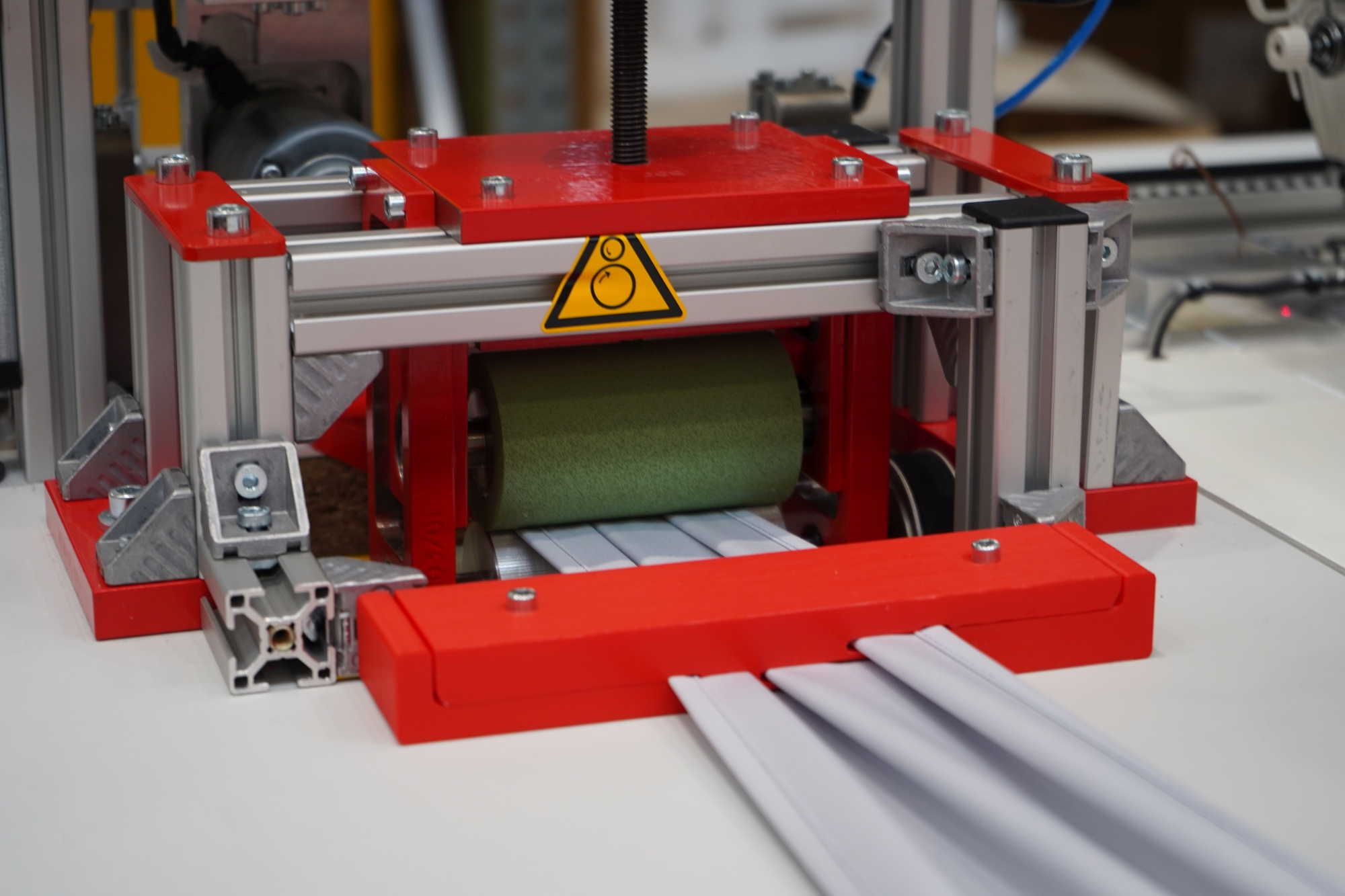

Building on our experience in the interlinked production of composite preforms, we have developed technologies that enable the automated production of garments and other textiles. This technology holds a great opportunity to contribute to the re-industrialization of textile production even in high-wage countries.