- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

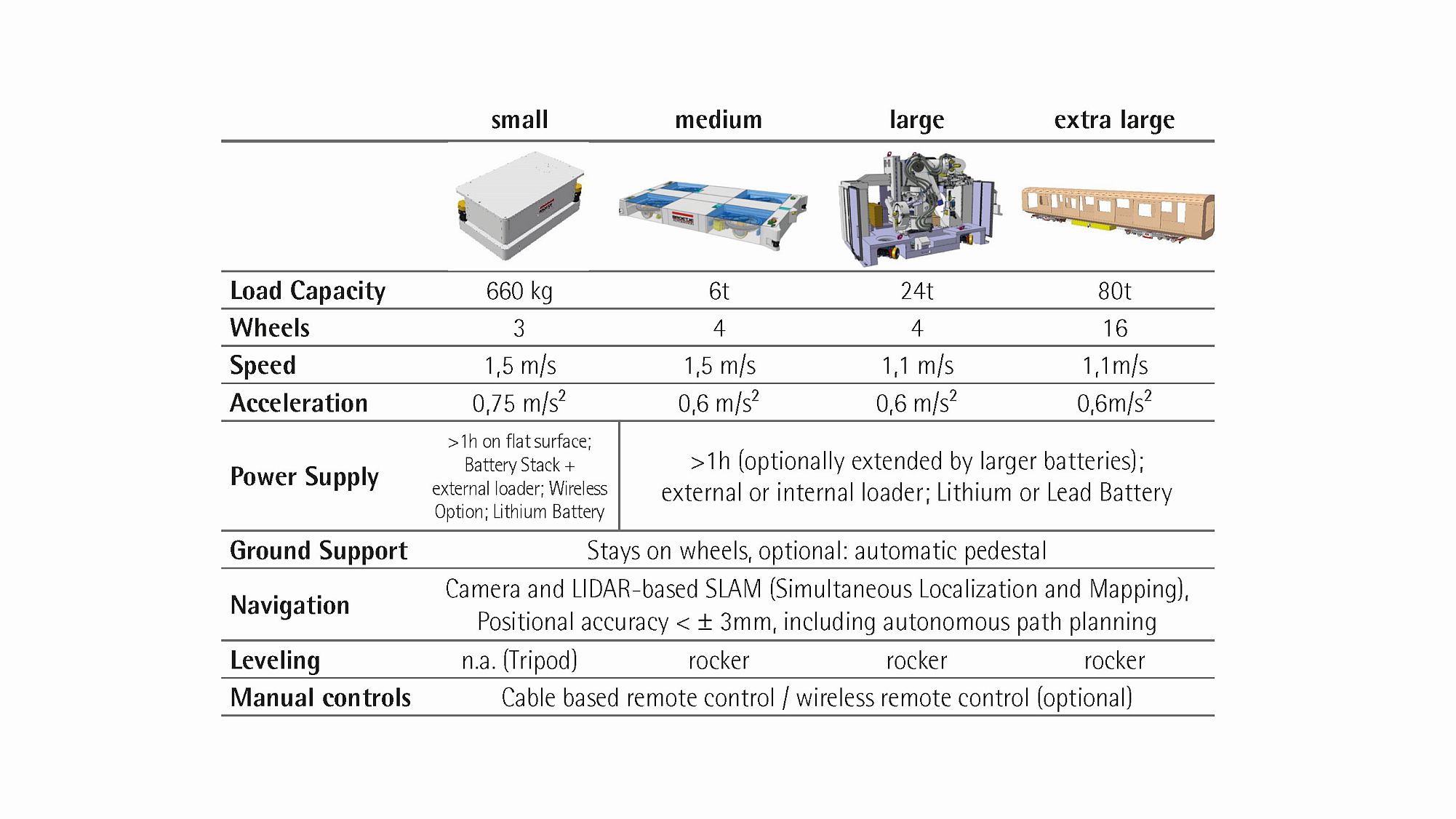

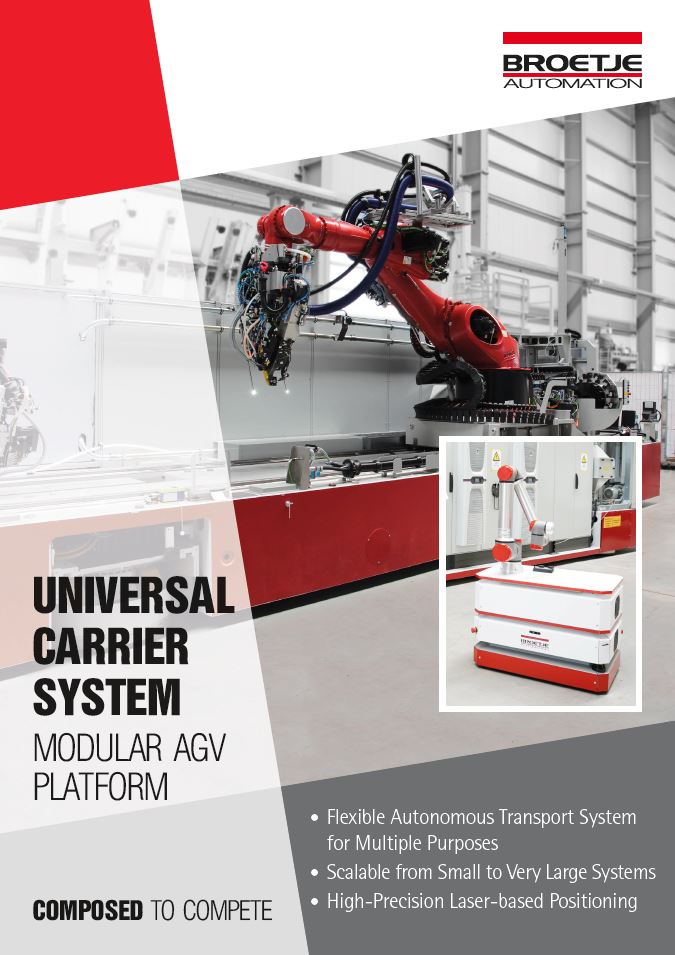

The Universal Carrier System is a modular, scalable AGV platform (AGV – Autonomous Guided Vehicle). It is highly configurable and the ideal solution for industrial manufacturing environments. From small cobots to complex machines and logistics systems, Broetje-Automation offers AGVs based on the Universal Carrier System with a large variety of load capacity and high-precision positioning. The innovative SLAM navigation system is based on latest LIDAR technology.

Combined with the proprietary omnidirectional wheel technology the system offers highest flexibility, robustness and precision for your production environment. Proven standard components ensure low operating costs and easy maintenance. In combination with our state-of-the-art software, the universal carrier system is perfectly qualified for clean floor automation in industrial production.

By loading the video, you agree to YouTube's privacy policy.

Learn more

Special Features

360° Wheel Design

- Universally scalable for all platforms

- No angle of rotation limit – endless steering movement

- Simple design with standard, off-the-shelf parts

- Assures robustness, no moved cables

Control and Navigation

- Safe Hand Pendant Operation (wireless or cable as backup)

- Camera and LIDAR based SLAM (Simultaneous Localization and Mapping) including path planning

- Monitoring and control can be done with mobile clients

Customized Design

- Load and form can be designed according to task

- Scalable capabilities by size and number of wheels

- Standardized off-the-shelf components

- Power storage on the plattform

- Optional lifting axis for stabilization, locking devices to fix load or standard containers, any kind of position controlled axis or couplers

Universal Carrier System Product Information

Download our product flyer for more detailed information about the AGV´s.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.