- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

Production technology for the Energy Transition

Published on 11 July 2022

Broetje-Automation automates assembly for wind turbines

Broetje-Automation supports the energy transition with automated production technology for the offshore wind industry. Building on more than forty years of experience in the automation of assembly processes of very large components, the company based Rastede, Germany has achieved significant improvements in quality, efficiency, and cost-effectiveness with its automatic bolting system.

Industrialization of the production of wind turbines

Wind energy is regarded as a key sector for ensuring long-term energy security, climate protection and future viability in industrialized countries. The industry is facing the challenge of mastering unprecedented growth while at the same time rapidly developing technology. Production capacities must be expanded quickly in order to achieve the expansion targets set. This requires innovative approaches in production and new thinking in the processes.

At the same time, the individual turbines – especially in offshore wind energy – are getting bigger and bigger, which is creating new challenges in logistics, transport, and assembly. The requirements for accuracy, quality and documentation are also increasing. In addition, the shortage of skilled workers and demographic change are limiting growth in the industry.

By loading the video, you agree to YouTube's privacy policy.

Learn more

Innovations from production technology for wind power

The technological fields of action are diverse. Today’s wind turbines, for example, require a large number of high-strength screw connections. “Accuracy is important here, because it must be ensured that every single fastener is bolted with the right torque and, if necessary, tightening angle. Ergonomics and safety for the workers, some of whom must carry out work at high heights due to the very large components, also represent a challenge,” explains Oetken.

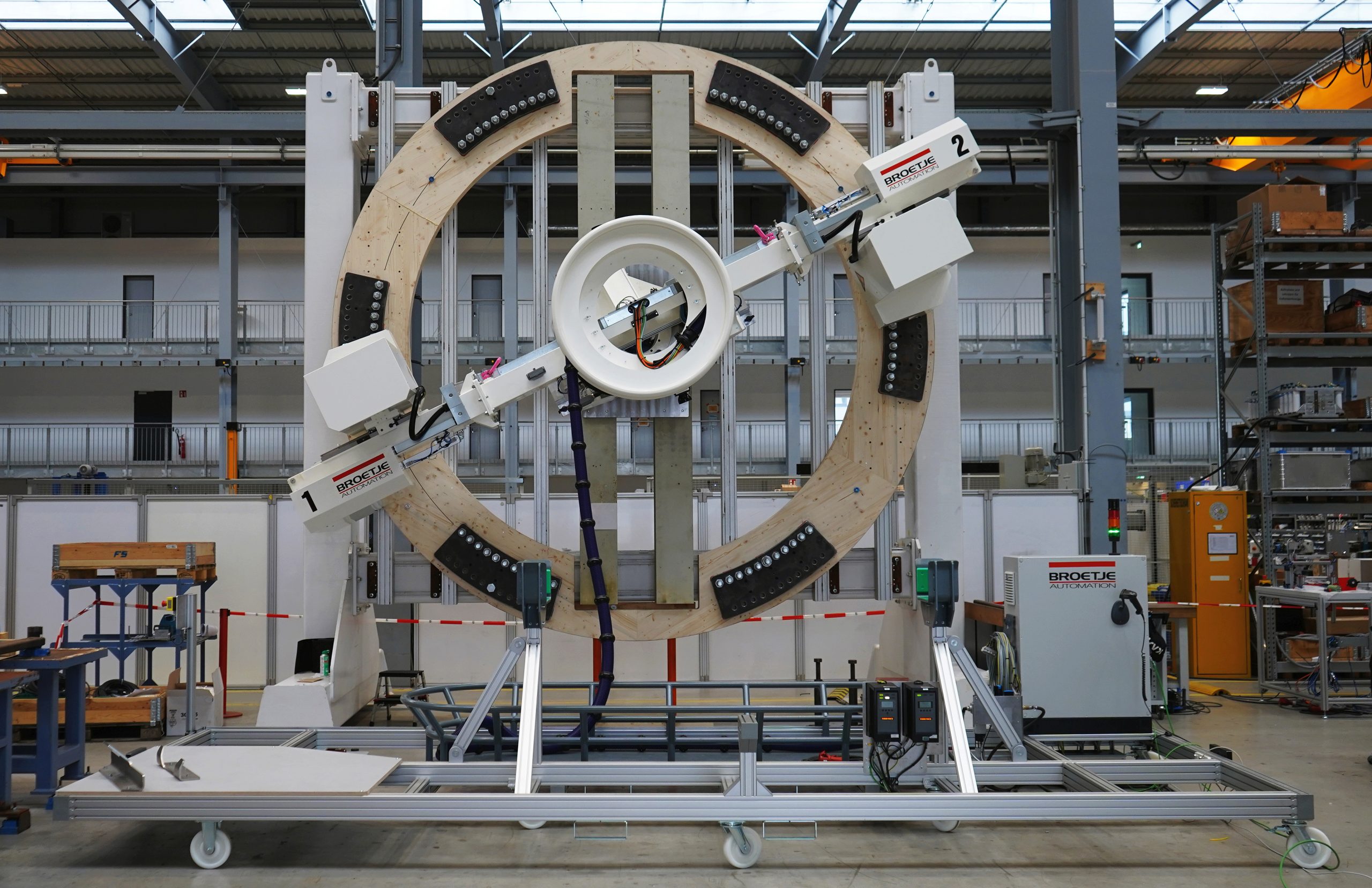

The “Rotary Torque System” developed by Broetje-Automation for a European customer solves this task. As a retrofit solution, it was important that the automated system fit seamlessly into the existing production environment. The system is therefore designed as a mobile and lightweight unit that can be used flexibly on several production facilities. It is fixed centered on the component and is thus able to run automatically pre-programmed screw connection processes without further manual work .

Mobile machines as a solution for large components

The larger and heavier the components to be assembled, the more sensible it is to bring the machine to the component instead of providing fixed machine workstations. This trend is already established in other industries, such as the aviation industry. For this reason, Broetje-Automation has specifically built capabilities for mobilizing machines and systems. The existing positioning technology – both globally in the factory and locally for the recognition of the components – promises further potential in the future.

Digitalization of production

The Rotary Torque System implemented by Broetje-Automation bolts two opposite bolts in parallel. The torque is absorbed by means of a torque support on the high-precision, electric screwdriving tools. The opposite arrangement ensures the tightening process (similar to a car tire) and the cycle time.

The positions are automatically approached and both fastening processes are controlled synchronously. Depending on the customer’s requirements, the existing technologies for digital factory integration at Broetje-Automation can be used. This starts with the planning of the processes and the layout and continues with simulation and offline programming based on digital twins. This trend will intensify in the future, as the reduced quality costs, especially in the case of large and complex components, are a major lever for increasing efficiency, avoiding errors and improving cost-effectiveness.

Broetje-Automation already incorporates sensor systems (e.g. laser, camera or radar guided) in numerous systems as well as the digital integration for simulation based on the Digital Twin, offline programming as well as inline quality assurance and documentation in order to be able to offer its customers a holistic solution to their production challenges. “For the future, we expect that even more technologies from our portfolio will be used,” Thomas Oetken dares to take a look ahead. In particular, the ever-larger rotor blades still hold a lot of potential. Broetje-Automation is already working on optimising the existing industrial lay-up technology for fibre composite structures for this area as well.

The transition to automated production in the wind power industry will not happen overnight. It requires a holistic approach to examine the upstream and downstream processes in order to use automation sensibly. “This will be a joint learning process between mechanical engineering and the wind power industry,” Oetken is convinced. “If we do it right, automation has the potential to stop the migration of production jobs abroad and bring more added value back to domestic regions.”

Gallery