- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

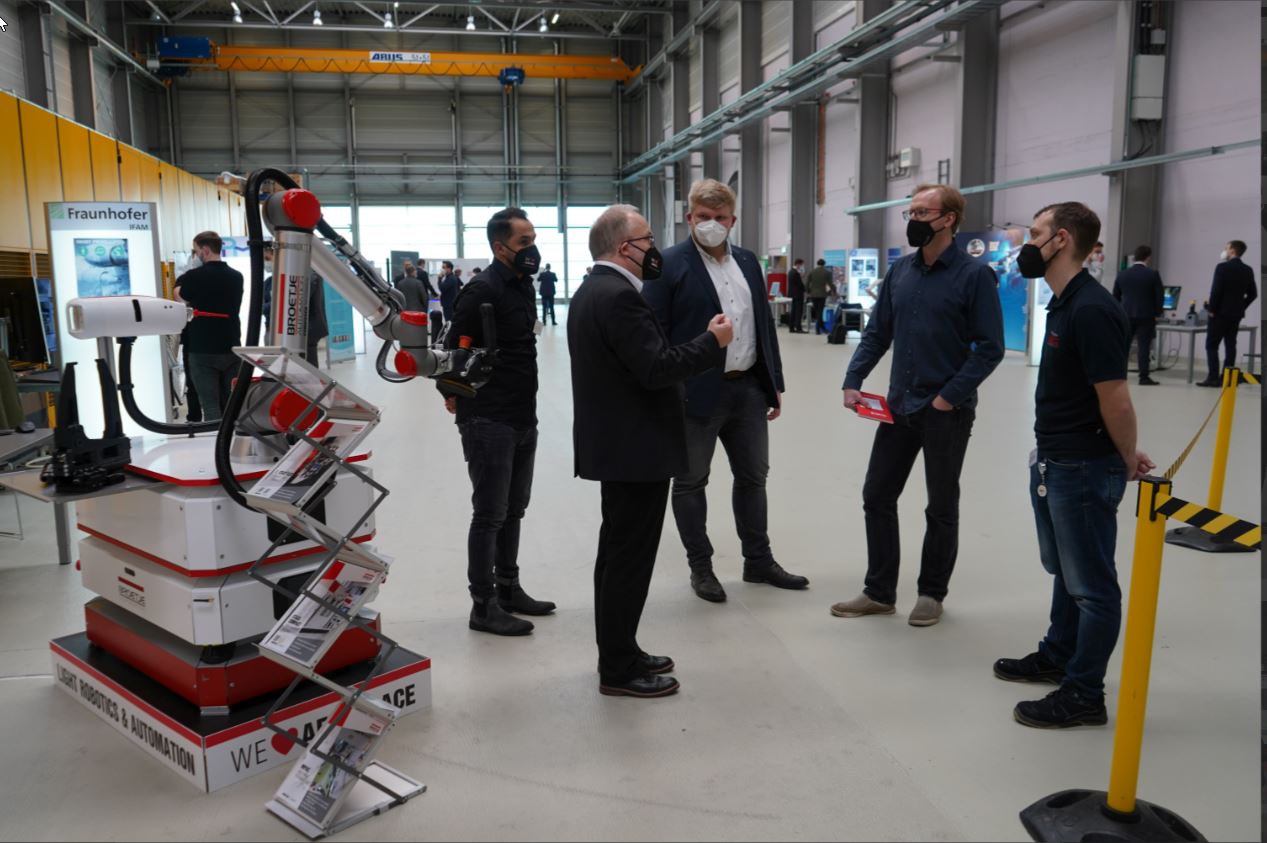

Vertical END2END: Showcase for Digitalisation in the Factory of the Future in Varel

Published on 18 March 2022

he Factory of the Future will only be possible if all levels, from planning to machines on the shopfloor, are digitally interconnected. Eight partners from research and industry have joined forces to make this a reality. The first sprint event for the “Vertical E2E” project, funded by the Lower Saxony NBank, has now taken place.

Presentation of the Vertical E2E Project

Under the leadership of Premium AEROTEC, the partners will develop innovative approaches for the optimization of digital assembly processes within the “Factory of the Future” over the next two years. In addition to Broetje-Automation as an automation and factory specialist, the Laser Zentrum Hannover e.V. (LZH), the IPMT – Institute for Production Management and Technology at the Technical University Hamburg-Harburg, Marposs, Fraunhofer IFAM, IFW – Institute for Manufacturing Technology and Machine Tools Hannover, GE Additive as well as DESOUTTER GmbH belong to the Vertical E2E project consortium.

A special focus is on human-machine collaboration. Here, Broetje-Automation contributes with its experience from several years of developing collaborative robot systems – so-called “CoBots”. As one of the first companies in the industry, Broetje-Automation has focused from the beginning on the implementation of part manipulating processes with the help of cobots. Previously, cobots were rather used for handling and logistics activities. With the help of the technologies developed by Broetje-Automation, various industrial applications such as drilling, grinding, sealing as well as riveting are now ready for use.

Digital integration plays an essential role in this context to ensure high efficiency and cost-effectiveness. The aim of the Vertical E2E project is to create vertical digital interconnection across the various production levels from ERP (Enterprise Resource Planning) and MES (Manufacturing Execution System) through line management to the individual machine. The prerequisite for this is extensive and secure networking at the digital level. This is where Broetje-Automation’s Digital Twins, which have been established for several years, and the new technologies for collaborative and mobile robots with variable end effectors come into play.

In this way, the project also lays the foundation for better linking the digital and analog world in the Factory of the Future and for enabling vertical integration in industrial manufacturing.