- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

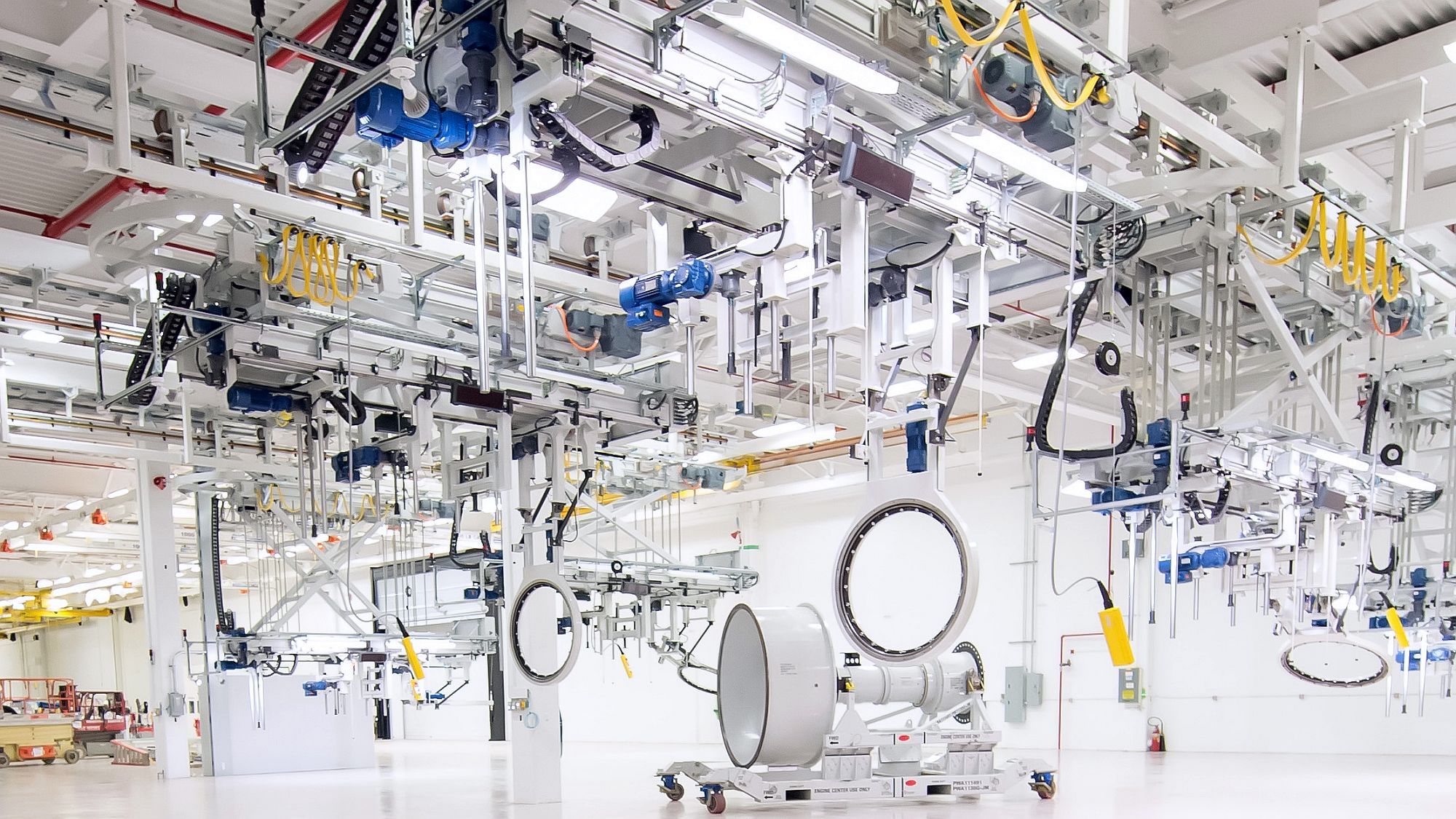

To create the Factory of the Future, many adjusting screws interlock. At Broetje-Automation, everything is organized for this. Our machines, robots and mobile systems form the basis for automated, flexible and reliable production systems. Specialized software solutions complement the hardware and thus form the core of the outstanding quality of our production systems.

A broad product spectrum based on more than 40 years of experience

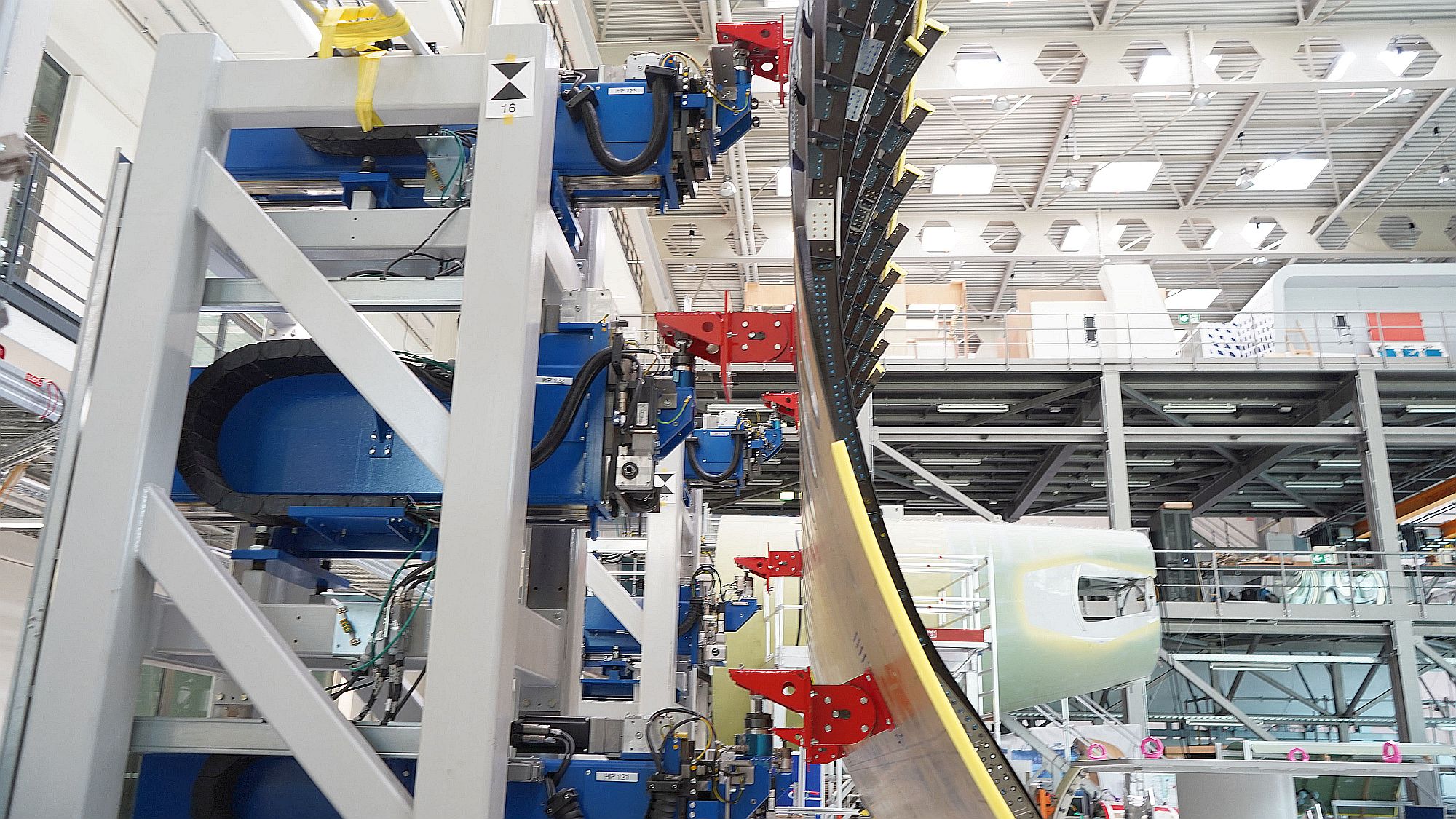

Our experience and process know-how guide us on the way to advanced systems that exceed our customers’ expectations in terms of quality, productivity and accuracy. Industrial applications such as drilling, riveting, sealing and milling enable diverse industrial processes in the Factory of the Future.

But there is much more to a production plant! Through interconnected digital solutions, our machines and the entire production line communicate with each other. Here, process data avoids collisions in real time and, based on real NC machine data, the process of the entire production line can be digitally planned, simulated and efficiently controlled during operation. This is a relief not only for the employees, but also for the quality assurance of the end products.

Service and Support through the whole lifecycle

With the standardization of the components and the commissioning of the equipment, our Key Enabling Services come to the store. An orderly and well-planned implementation of the systems releases the desired synergy effects and lifts your production to the next level – efficient, flexible, precise and designed for high demands.

For long-term support, we are at your disposal with competent service even years after the implementation of the production line. To ensure that your production can be quickly resumed, we are close to you – at 23 locations in 7 countries – ready for action around the clock.

As an environmentally conscious company, we extend existing machines at our customers’ production sites with our retrofit services. In this way, we not only extend the life cycle and save resources before new equipment is purchased but also contribute to the continuous improvement of our customer efficiency and profitability. A fully comprehensive concept of modern high-tech production always also includes the sustainable use of existing machines and materials.

Explore our Portfolio

Automated Equipment

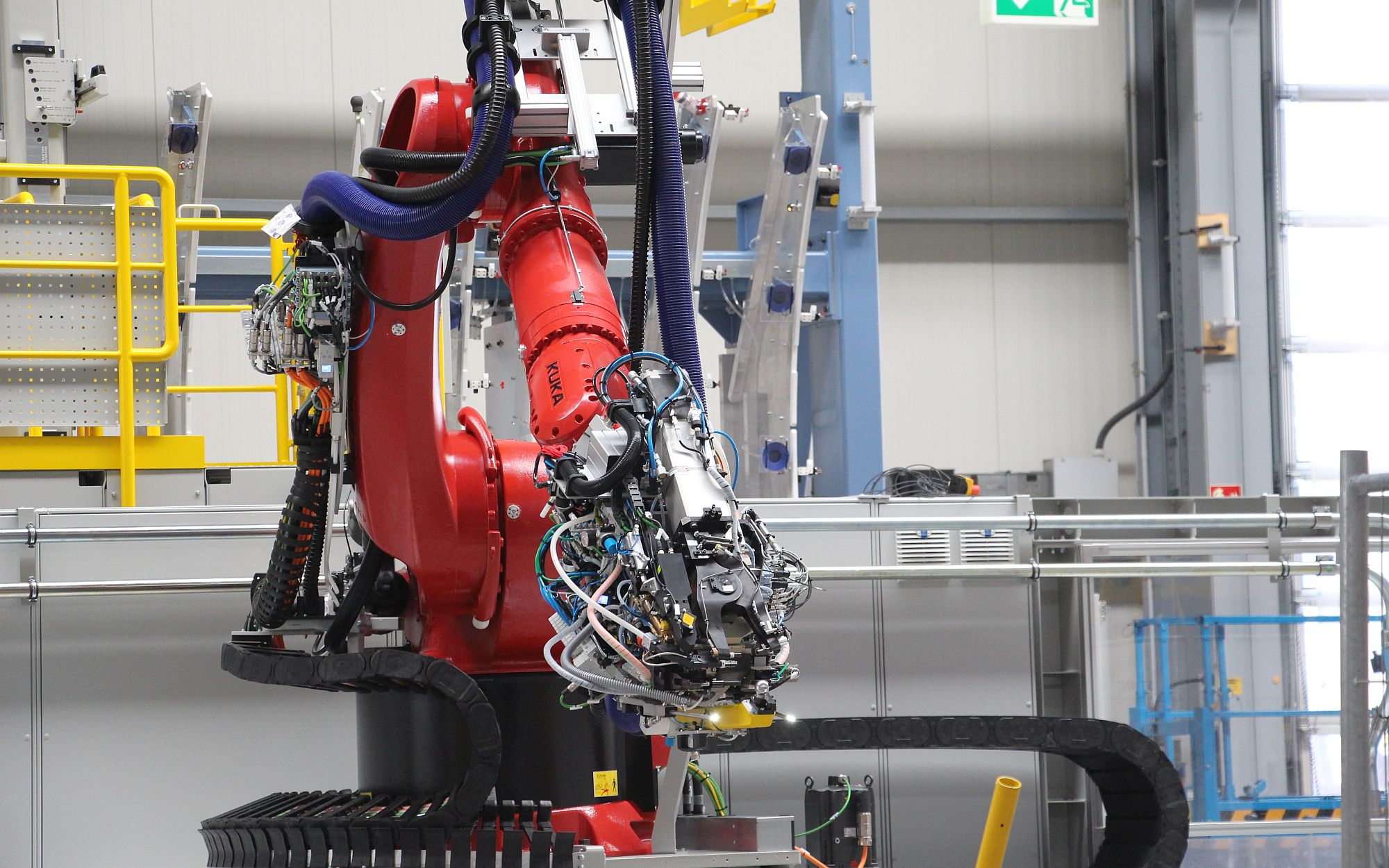

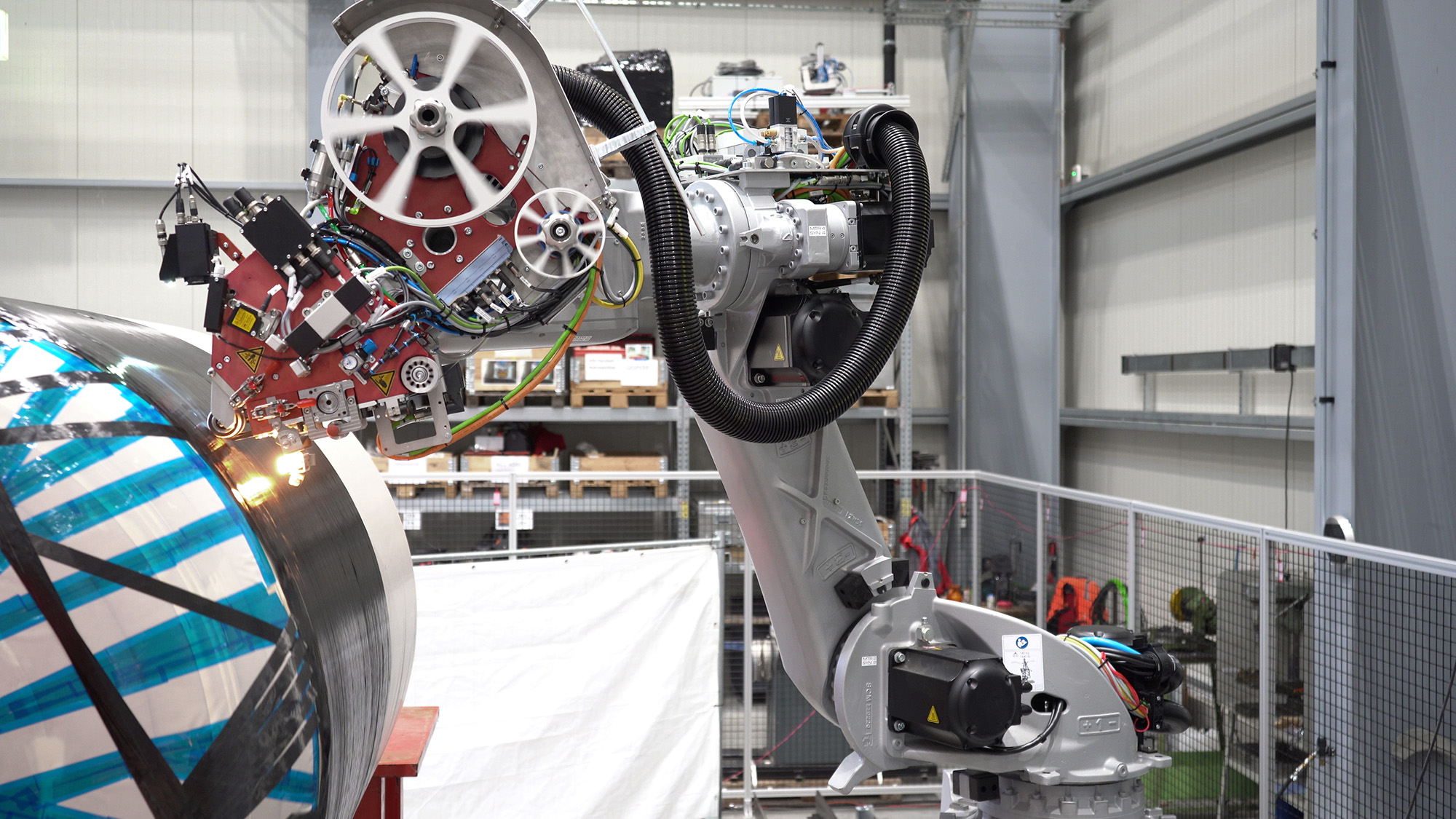

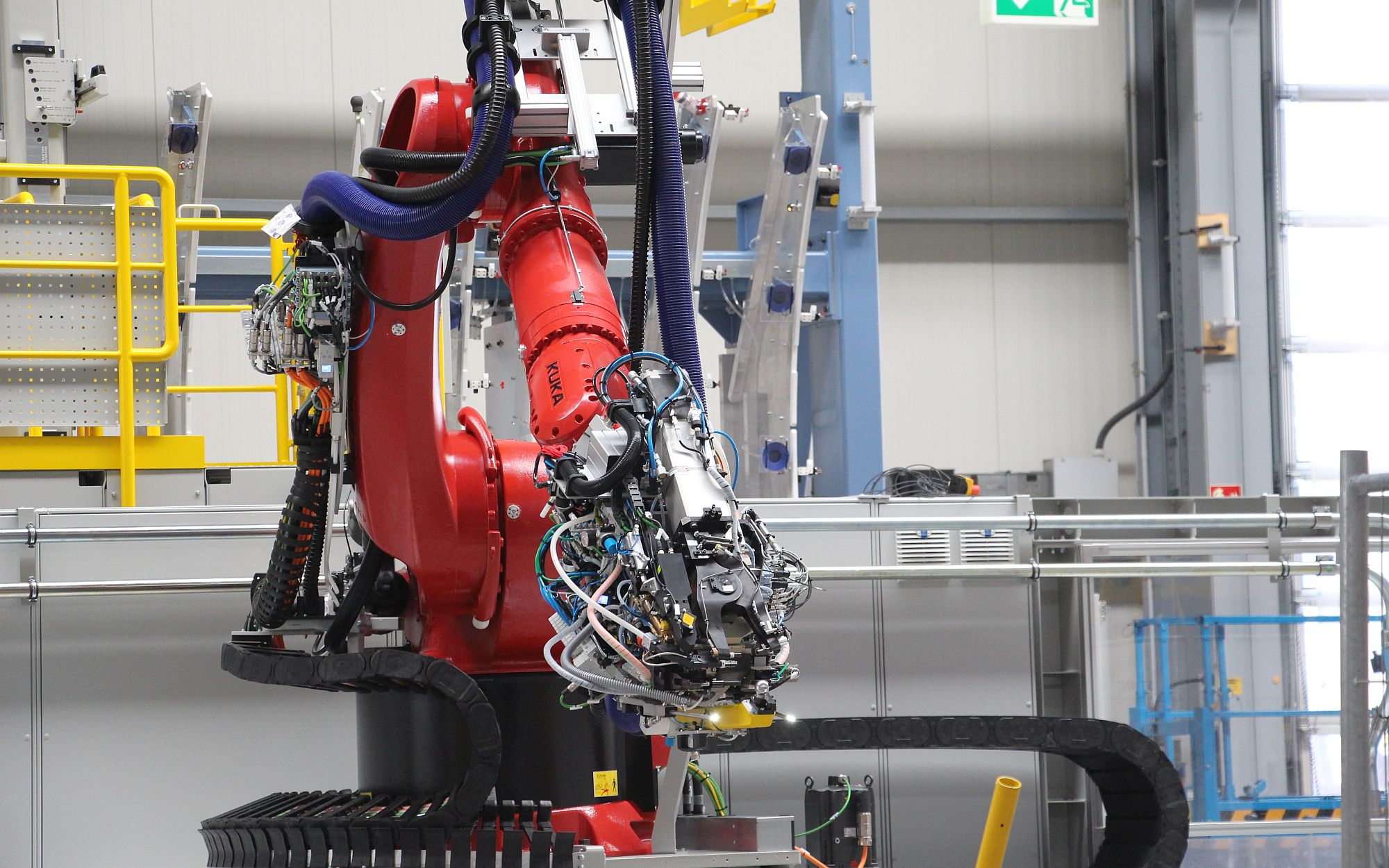

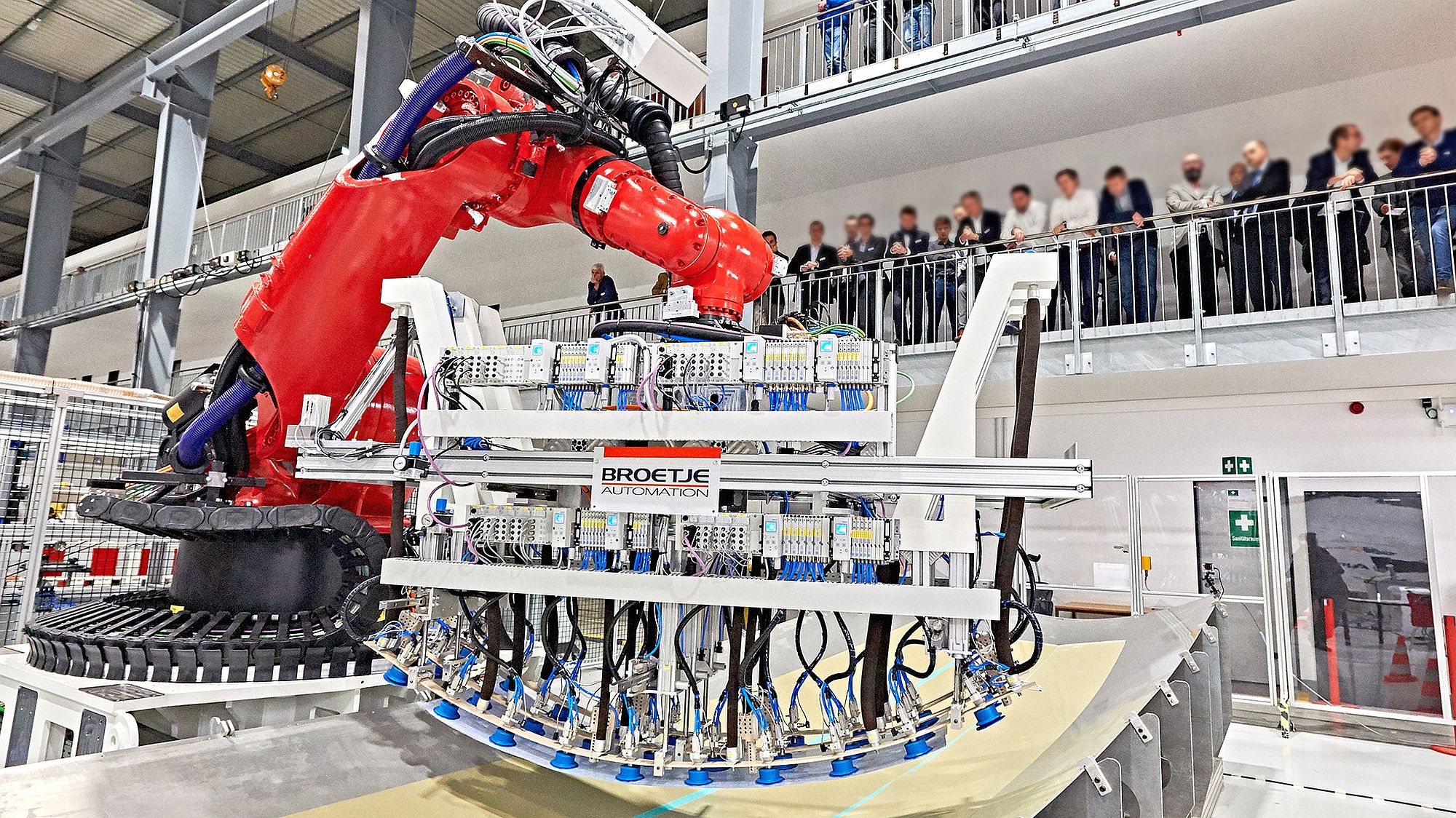

Automated solutions for the Factory of the Future comprise different systems for a wide range of industrial applications. From riveting machines to robotic systems with adaptable substructures and for various processes, we deliver customized solutions.

Smart Processes

Process know-how and implementation expertise for customized solutions lead to sophisticated and highly precise process quality. An indispensable attribute for good products.

Smart Factory

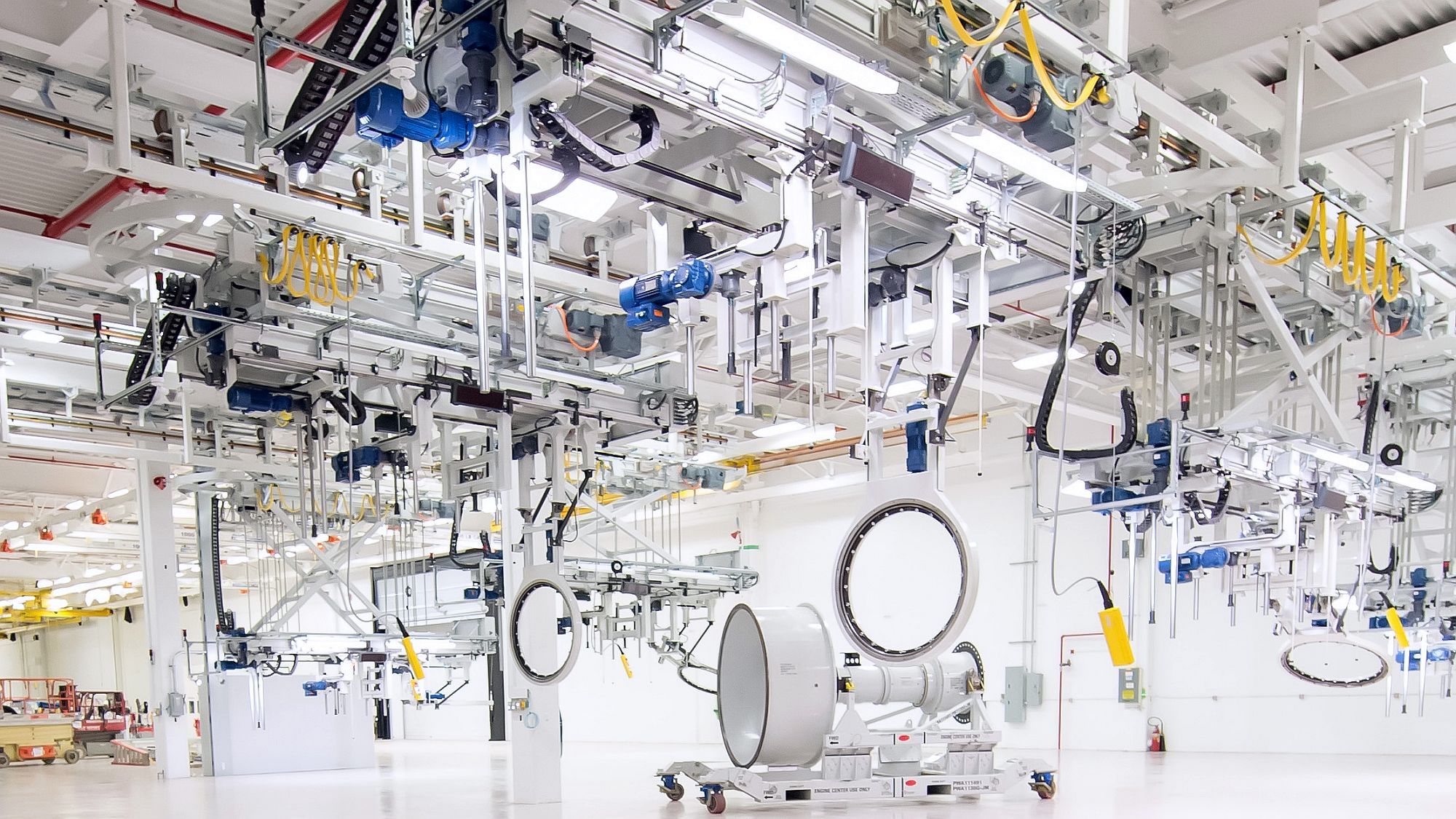

In the Factory of the Future, careful factory planning and in-depth expertise of the production systems integration are essential. At Broetje-Automation we are able to implement advanced technologies from factory planning, over turnkey realization to highly efficient production at our customers’ factories.

Key Enabling Services

As full service provider we deliver fast support around the world. Additional Retrofit services enhance the life cycle of ageing machines. With regular software updates, advanced electrification or even partial redesign Broetje-Automation is able to increase the productivity and quality for prolonged production without the effort of a complete machine renewal.

Insight into our product portfolio

As a high-tech company, we offer tailor-made solutions to our customers. With our many years of knowledge in the field of automation, Broetje-Automation is able to implement various solutions for maximum efficiency on the shopfloor.

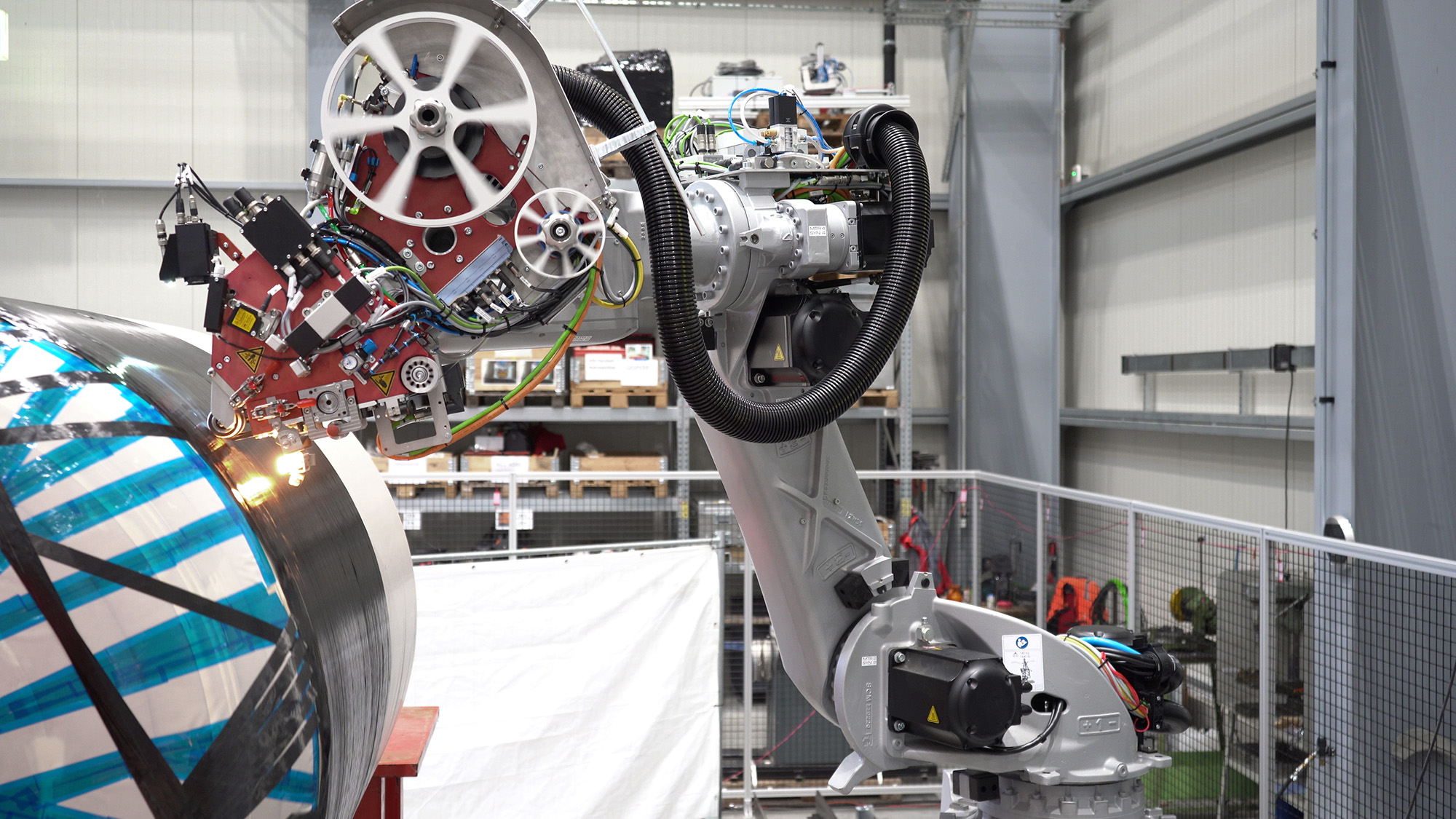

The RACe aerospace robot achieves the highest forces and accuracy while maintaining the flexible characteristics of a robotic system.

A Flexible Robotic Assembly System for highest levels of automation even with narrow and complex contours.

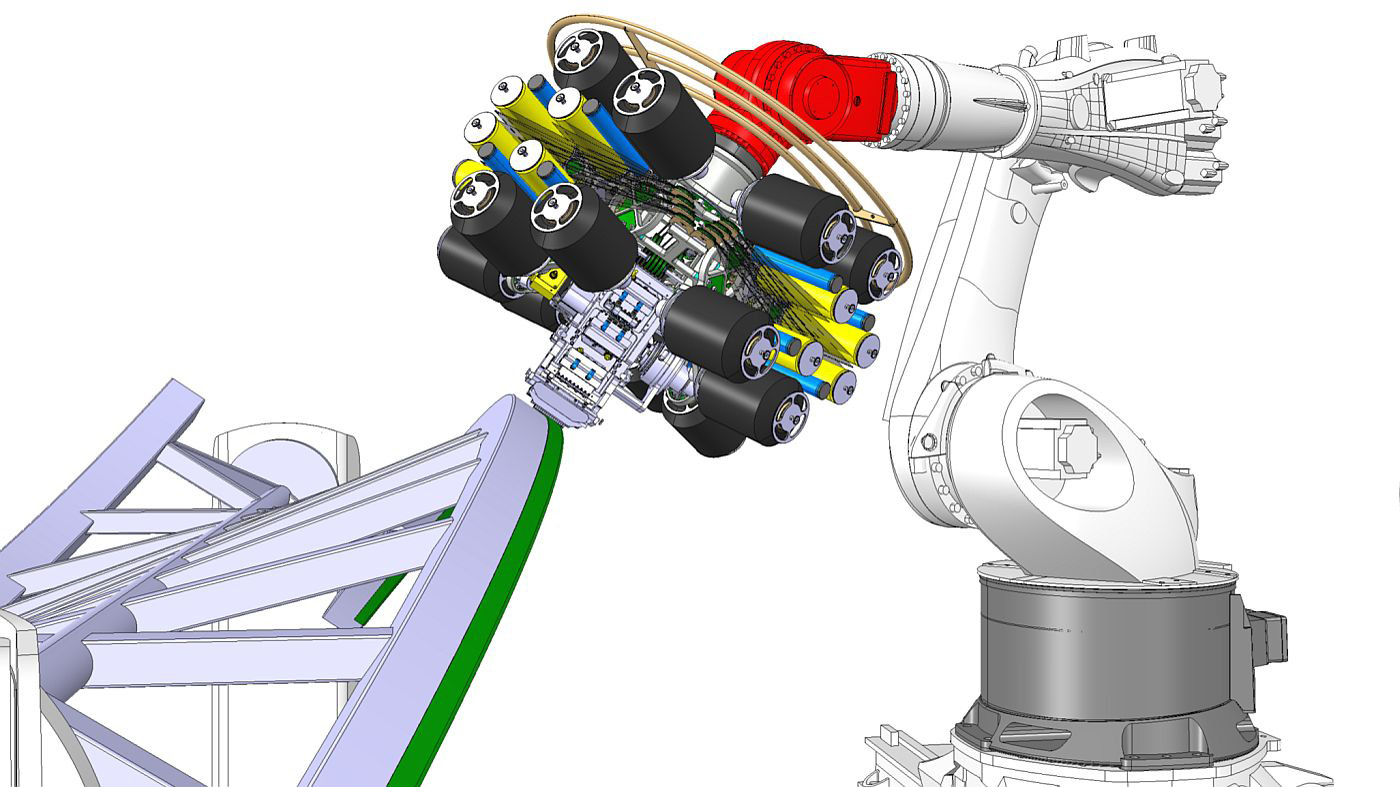

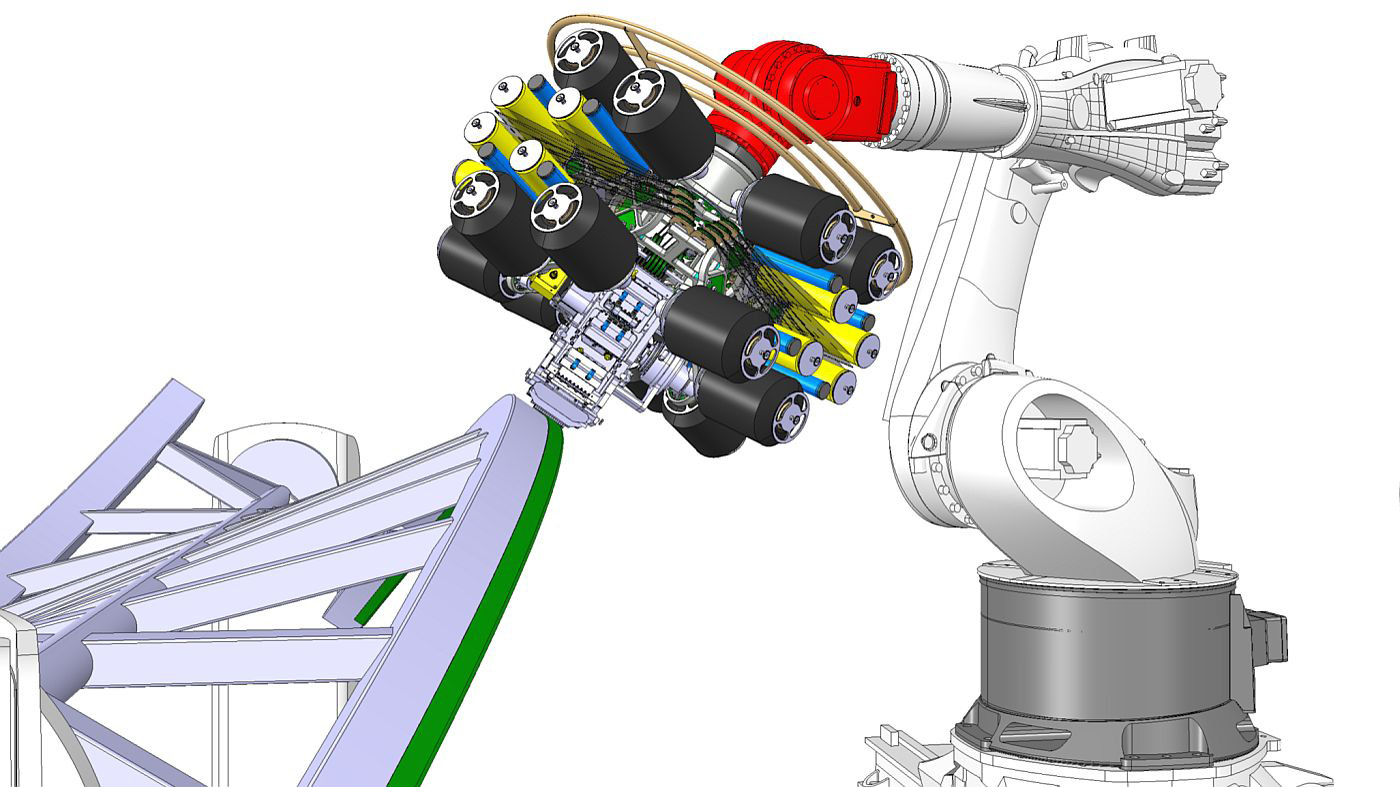

The STAXX One combines a flexible and reliable system for prototyping and the development of new structures and parts.

The total of 16 tows built into the STAXX Flex result in a versatile system with high efficiency and at the same time easy handling and maintenance.

Automotive-oriented component carrier system for easy loading, transfer and unloading of components.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.