- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

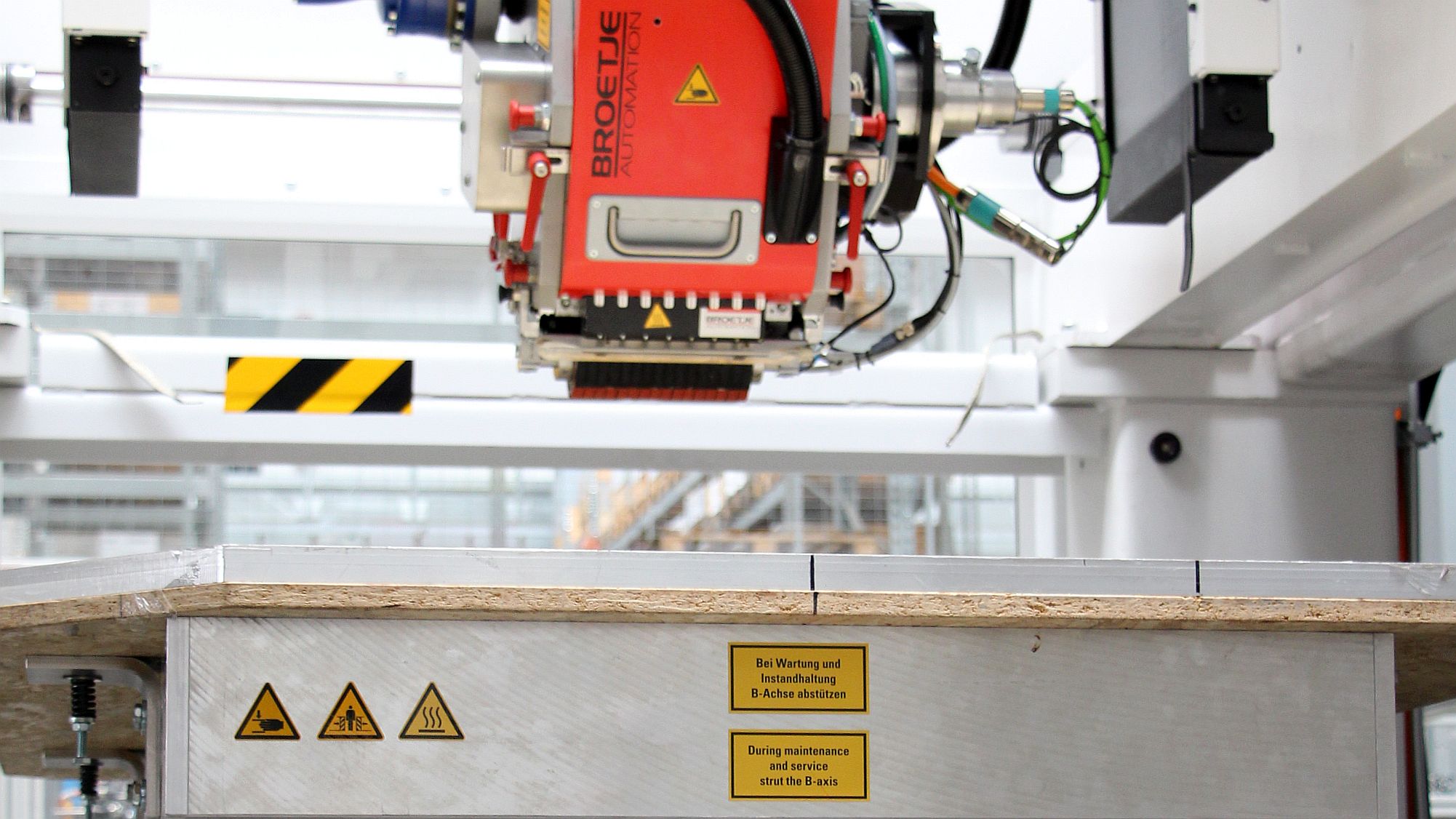

The STAXX 3D offers various options for high-volume production. The swiveling rotary table offers even more possibilities to produce small individual composite parts such as ribs, flat plates, structural parts and tailored blanks. This system is not only highly flexible, but achieves high part quality in a time-saving manner. Designed for a cost-efficient and sustainable production it is ideal for the automotive and aerospace industry.

Technical Data

- 16 tow AFP Head ¼” or ½”

- Layup area max. diagonal 2500 mm

- 6-axis (x, y, z, a, b, c)

- Tilting, rotary table

- Feed rate 60 m/min

- Cut on the fly with 45 m/min

- Direct layup of unidirectional carbon fiber

- Totally enclosed and air conditioned system

- Integrated pallet handling system

- Siemens 840 D SL Control

- High volume production

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.