- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

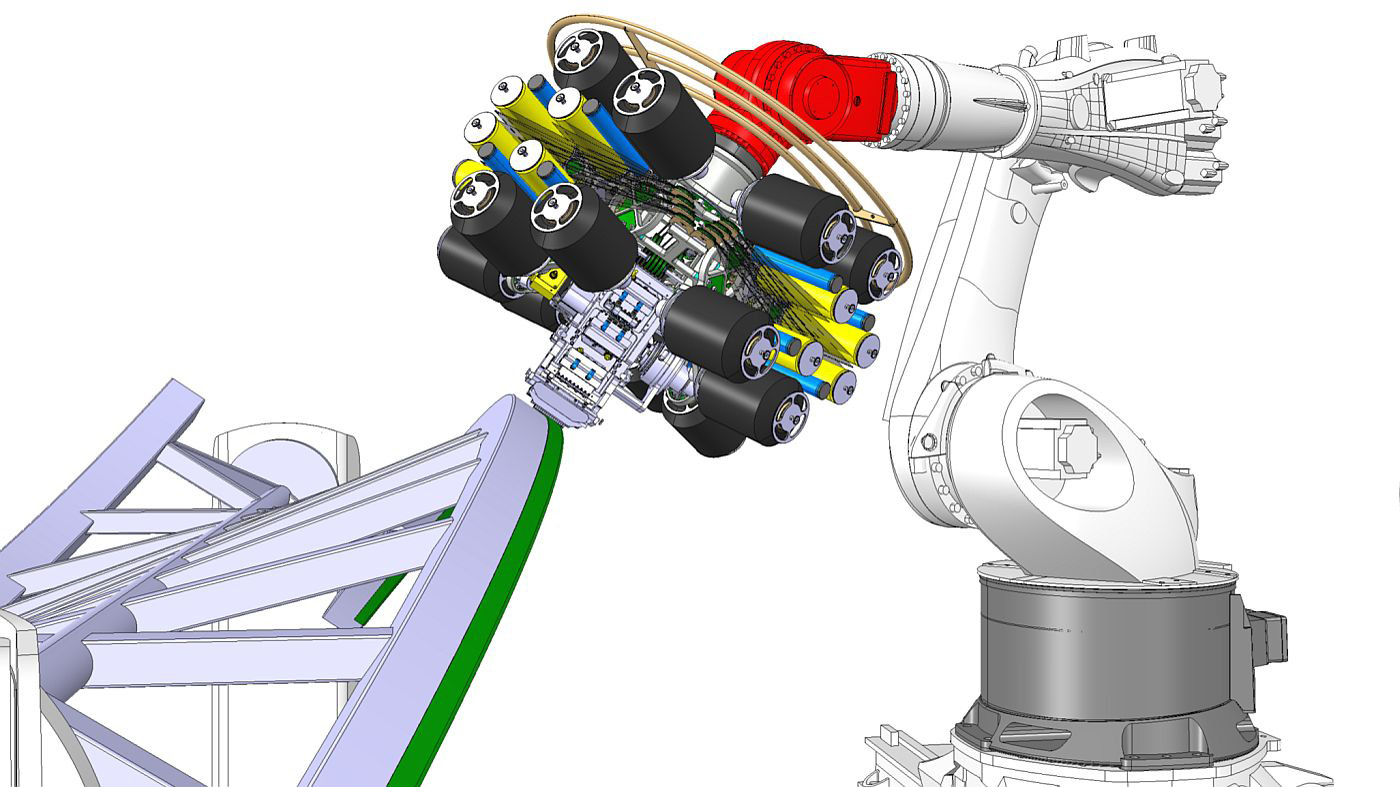

The STAXX FLEX is a high performance automated fiber placement end-effector for complex two- and three-dimensional parts. Its low weight of 440 kg including material enables it to be mounted on standard industrial robots of the 500kg class. The system is ideal for automated fiber placement in serial production. It supports common materials such as PrePreg and Dry Fiber up to 50K per tow.

The open, modular design ensures good accessibility to all components and quick and easy maintenance without tools. An automatic changing device can be integrated to further increase productivity. This allows maintenance work and material loading to be carried out parallel to the laying operation.

Technical Data

- Net weight 280 kg / 620 lb Including material 440kg / 970 lb

- Max. laying speed 60 m/min

- Cut on the fly 45 m/min

- Segmented compaction roller for even distribution of compaction force to all tows

- 16 x 8kg material spools on board

- Female layup radius down to 800 mm

- Material flexibility: Thermoset and Thermoplast ¼” and ½”

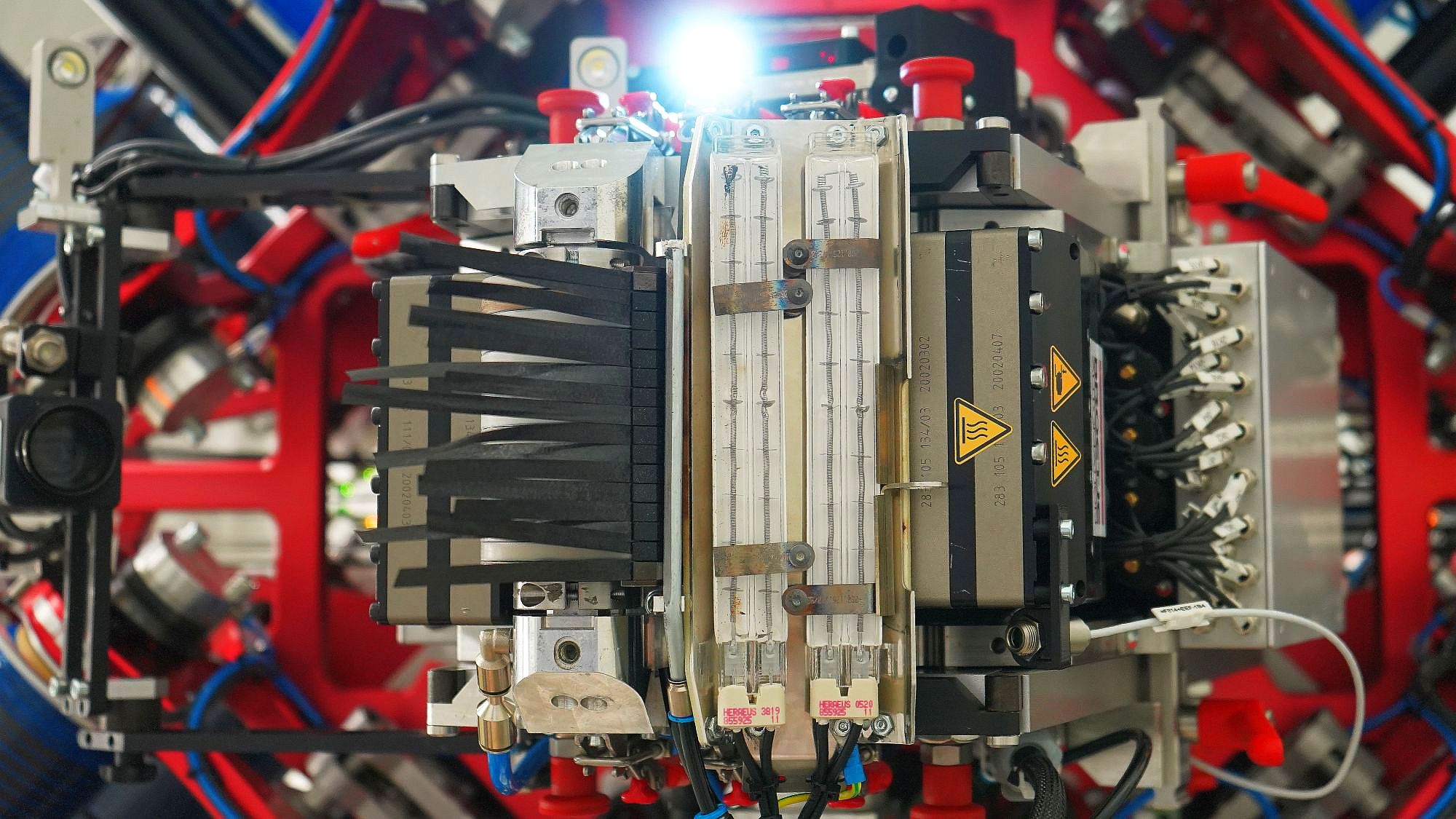

- Heating unit utilizing IR lamps or laser diodes

- Long-life cutting unit >10.000 cuts without rework

Special Features

High performance coupled with great versatility

- High performance at complex parts, designed for 2D and 3D operation

- Various material types (PrePreg, DryFiber, etc.)

- High depositing mass due to thehigh laying and cutting speed with 16 tracks

- Flexible use on a variety of positioning systems (industrial robot, machine style gantry, open gantry optional available)

Integrated Quality Control

- Constant compaction force

- Compaction roller following the contour

- Camera based inline ply inspection

- CAM system with digital twin for layup and performance simulation

Ease of use

- Open and modular design

- Ergonomic access to major components

- Changable standard components, service parallel to operation

By loading the video, you agree to YouTube's privacy policy.

Learn more

STAXX Flex Product Information

Download our product flyer for more detailed information about the STAXX Flex.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.