- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

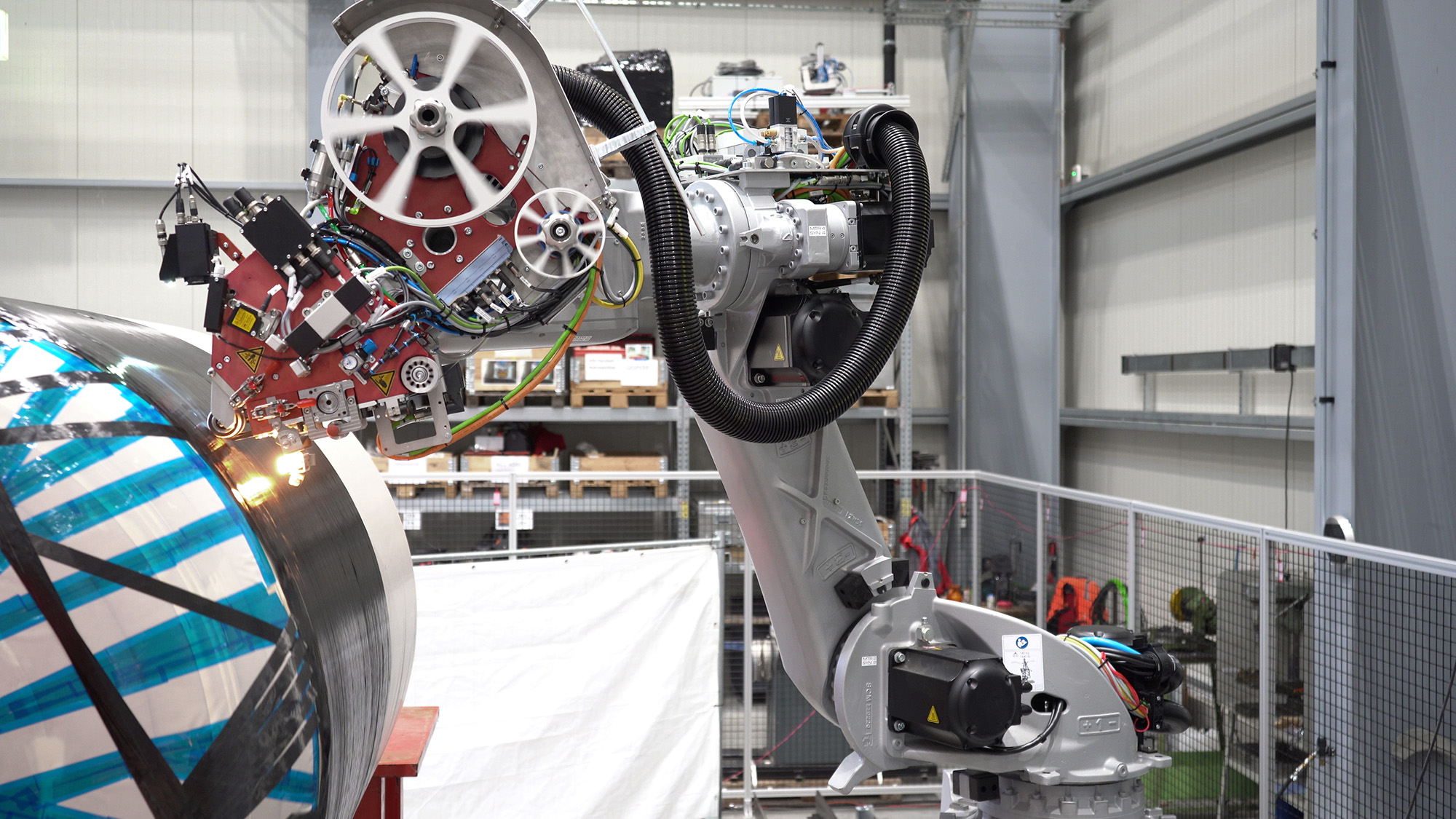

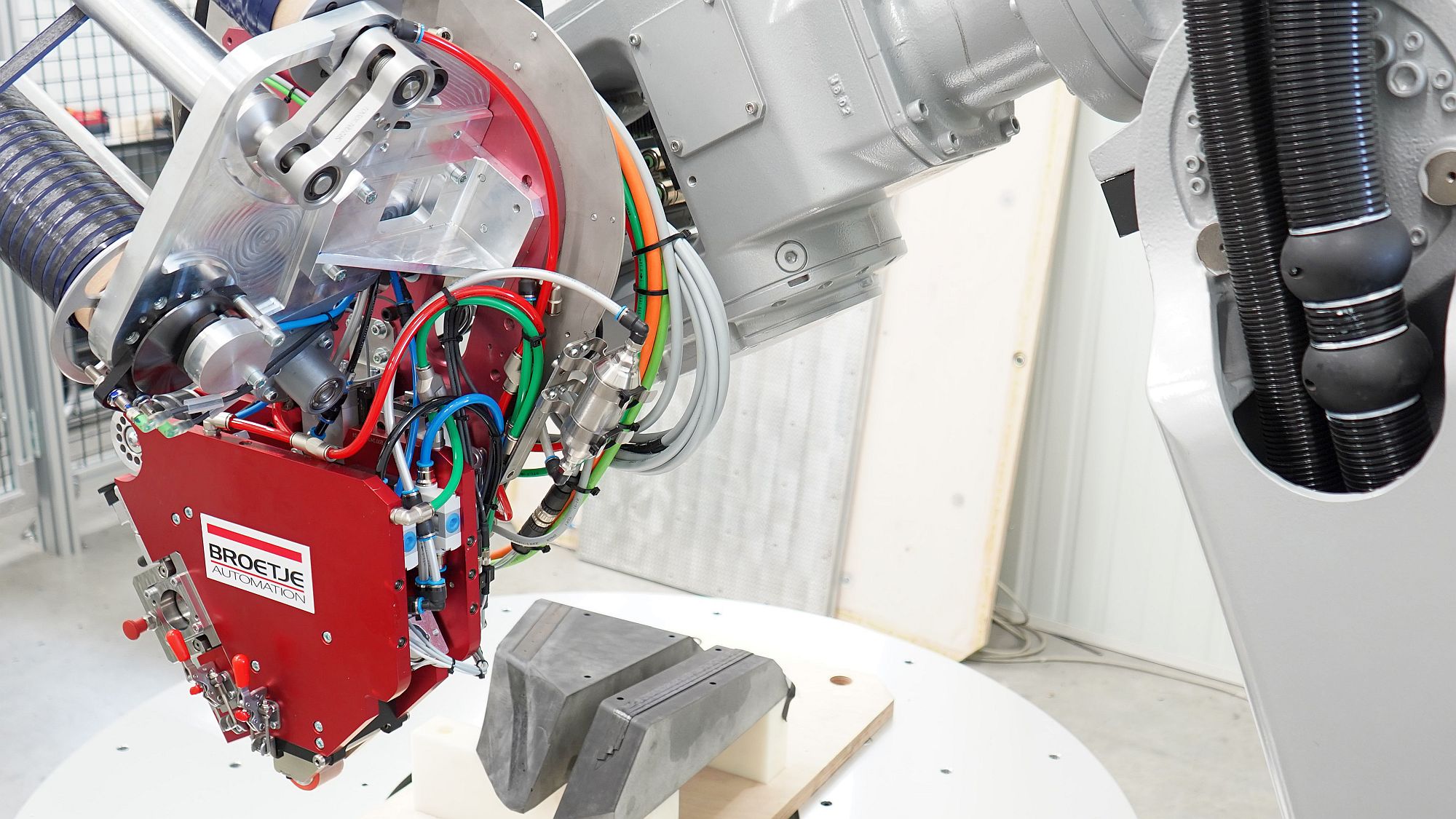

The STAXX ONE Single Tow End-Effector is a highly flexible small and lightweight automated fiber placement end-effector. With its mass of about 40kg it can be mounted on any standard industrial robot.

It allows automated fiber placement of complex parts and it supports a wide range of materials such as PrePreg, TowPreg and Dry Fiber material. The optional heated layup table can additionally be equipped with an NC-controlled turning device.

Technical Data

- Material spool with tow tension control

Optional: Level measurement - Compaction roller out of stainless steel or anti-stick polymer coating

- Controlled pneumatic compaction unit force up to 30dN (~kg)

- Backfilm collection spool

- Internal water cooling for prepreg material

- Deflection roll

Optional: Tow break detection - Robust cutting unit for tows above 50k

- Controlled Heating unit with infrared emitter,

diode laser or flash-lamp - Material flexibility: Any given width from 1/8‘‘ width up to 2‘‘ (50,08 mm)

- 2 Sets of compaction rollers for ¼” and ½”

Special Features

R+D flexibility combined with industrial readiness

- Various material types (PrePreg, TowPreg, Adhesives, DryFiber, etc.)

- Flexible Material size

- Siemens NC Controls

- Good accessibility for complex parts

- Modular cell concept

Cost efficient approach

- No foundation needed

- Standardized system components

Digital Twin

- Cell Layout

- CAM System for offline programmin based on 3D/2D CAD data

- Collision analysis

- Simulation for both, machine and layup concept

STAXX ONE Product Information

Download our product flyer for more detailed information about the STAXX ONE.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.