- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

Our panel assembly cells provide highest flexibility with large workpieces and high performance in panel assembly for your fastening process. The different systems are able to work on diverse structures and in a variety of angles. This makes industrial applications such as drilling and riveting more efficient and compatible for challenging editing. A combination of our assembly stations increases the production workflow if needed even more and unlocks unimagined savings potential whilst automating your production processes to equip the Factory of the Future.

CPAC

The Clip Panel Assembly Cell is a high performance system that operates reliable and efficient with various workpiece constellations. An improved Acessibility enables further possibilities for component processing.

IPAC

The Integrated Panel Assembly Cell impresses with its small industrial footprint. Fast cycle times and proven reliability make this system attractive for all sizes of workpieces.

MPAC

The Multi Panel Assembly Cell is ideal for large parts such as wing covers or fuselage panels. It features fast reconfiguration as well as a high payload and high throughput rates which makes this solution even more flexible for panel assemly.

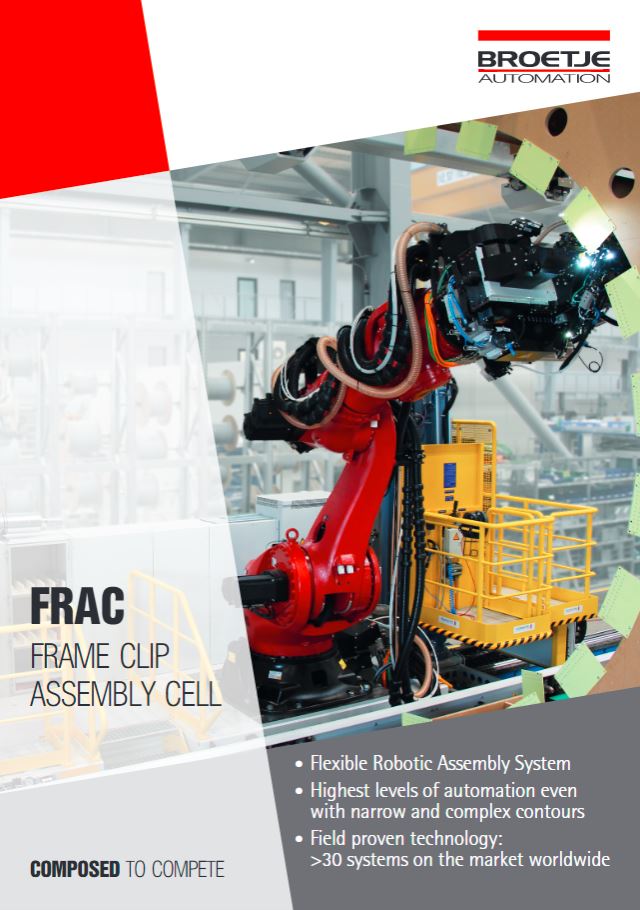

FRAC

The Frame Clip Assembly Cell is a flexible robotic assembly system with highest levels of automation even with narrow and complex contours. Its field proven technology is already integrated in more than 30 production sites worldwide.

Product Information about our Gantry Kinematic Systems

Please download more technical details on our Gantry Kinematic Systems here.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

Steady Winds are Rising – Broetje-Automation shows innovative approaches for the industrialization of turbine production

- Published on 12 September 2023

- Factory of the Future

- Fastening

Broetje-Automation has consistently pushed the boundaries of automation technology, delivering state-of-the-art solutions that enhance productivity, efficiency, and safety. Nowadays this knowledge is used in wind turbine manufacturing and assembly processes. With a commitment to sustainability and a focus on customer-centricity, the company’s presence at the Husum Wind Expo from September 12 to 15 is set to showcase its latest advancements and engage with industry stakeholders.