- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

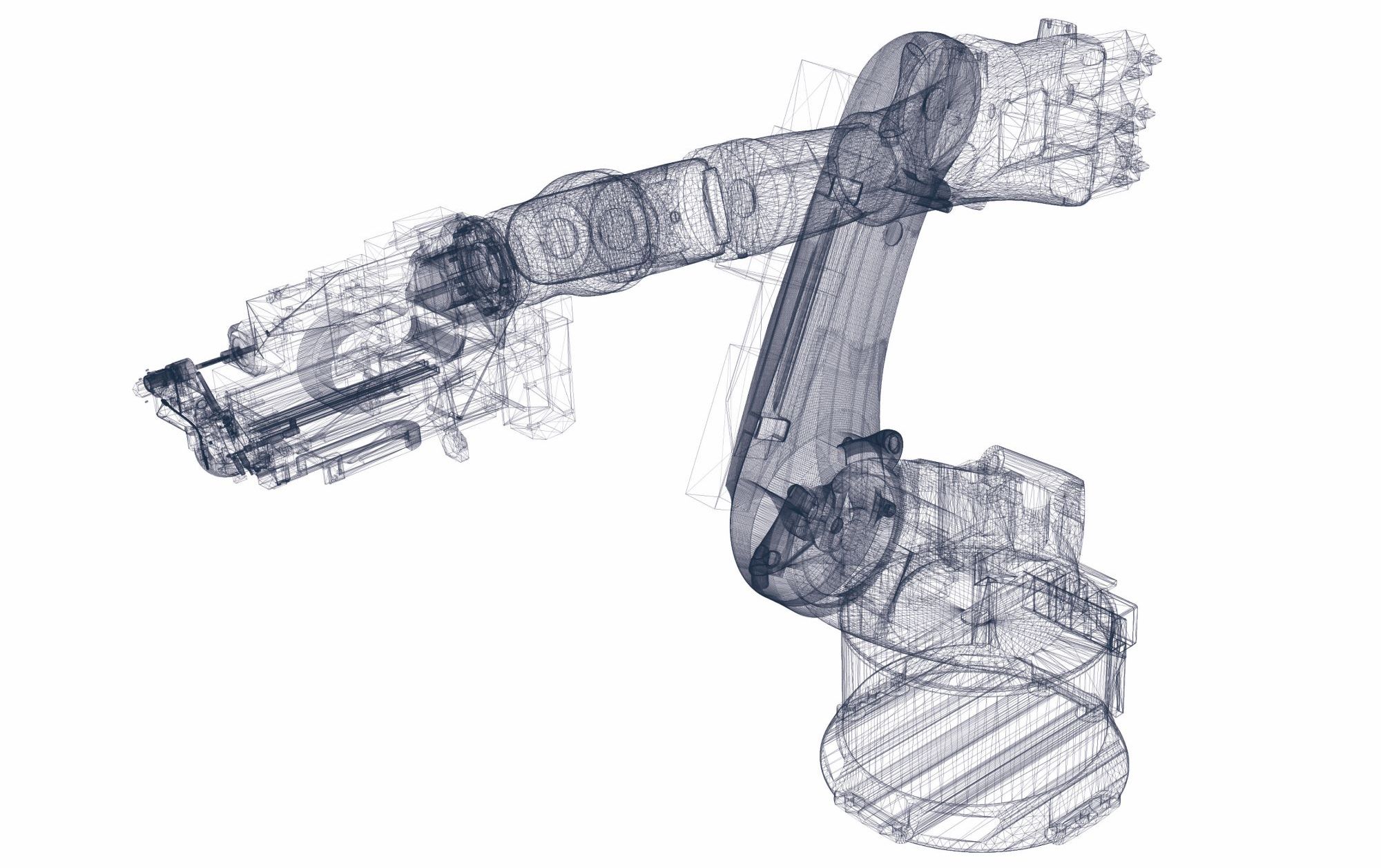

The Robot Assembly Cell (RACe) is a light weight solution for drilling of multi material aircraft parts. The solution is based on a robot with a high positioning accuracy in conjunction with a multi-task end-effector.

The high robot positioning accuracy is ensured with a special calibration and compensation developed by Broetje-Automation. The System provides you with high flexibility during various industrial applications and reduces the space capacity due to mobile or stationary platform options.

Technical Data

Operational Functions

- Automated Robot Positioning

- Product Referencing

- Product Clamping

- Drilling and Countersinking

- Product Unclamping

Single-Task End-Effector

- Drilling and countersink capability

- Drill spindle Torque: 10 Nm Spindle speed: 200 -18,000 rpm Drill chuck interface: HSK32E)

- Chip and dust removal with explosive protection

Positioner

- Standard 6-axes robot system

- Robot equipped with BA accuracy package Robot calibration Dynamic load

compensation Grid compensation Temperature compensation - Robot Positioning accuracy: ±0,3mm

Special Features

- High speed drill spindle (drilling quality better than H9)

- Hole roughness up to Ra 1.6 μm

- Drill chuck storage with 24 places

- Product referencing capability to ensure the edge distance to the structure

- Normality sensors to ensure a perpendicular alignment to the work piece during clamping

- Moving of platform by manual operated electric mover

- Manual fine positioning of platform by index bolts on air cushions supports

- Safety system with laser scanner

- The working area is not accessible from the rear side of the platform

- Robot system is prepared for future extension

- Control system: Beckhoff or Siemens

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.