- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

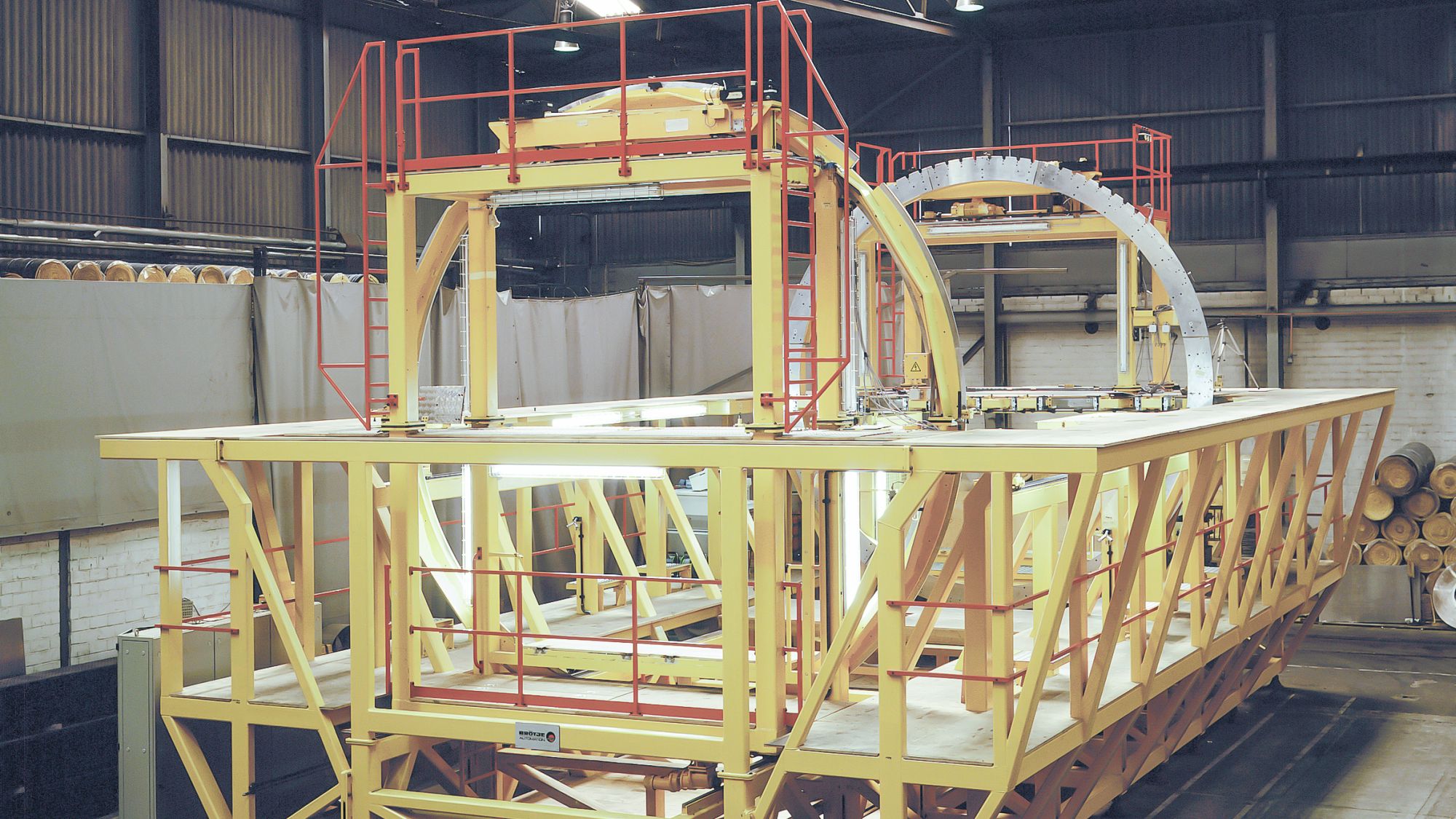

At Broetje-Automation we find solutions for various challenges around the shopfloor. This includes not only heavy machinery for industrial applications, but also a wide range of jigs and tools. We provide the factory of the future with the equipment it needs from assembly jigs to side line equipment to flexible automated multi-positioning systems. For high-quality assembly and compliance with tolerances, Broetje-Automation offers the right equipment – whether large or compact.

Our repertoire includes jigs and tools such as component carriers, storage and transport carts, trailers, special process equipment such as ramps, ergonomic workstations or storage options and measuring tools but also automated solutions by implementing a flexible multipositioning system in the production machines. For even more flexibility, safety and precision.

Our Jigs & Tools Segments

During the assembly of aircraft parts, the panels and structures are joined together to form an incredible final product. This requires different types of Assembly Jigs and large working platforms to complete the last of these assembly steps. With experience and drive, we stand for quality products made to measure to help our customers finish their project.

To ensure safe and high-quality production processes, our Line and Station Equipment can be configured for different applications and customer requirements. They thus enable safe and structured assembly, whether integrated into an entire production line or at a specific assembly station.

Precise positioning of workpieces using manual and automated fixtures is essential for all assembly and pre-assembly operations. In order to support and hold workpieces, the corresponding fixtures must take into account the required tolerances of individual parts and assemblies. Comprehensive concepts for reducing tolerance build-up during assembly and stress-free workpiece frames also ensure the highest manufacturing quality and a long service life for the end products.

This Equipment is designed for loading and lifting heavy cargo and ensures the safe transport of single parts as well as complete or partially assembled aircraft structures such as wings, fuselages or tail units.

Flexible tool handling adapts to the surface of the structures and creates maximum flexibility for the panel set-up. It also allows faster reconfiguration and is designed for a high payload. This system is suitable for various types of machines and is highly adaptable to industrial applications and customer needs in the aerospace industry.

Even more variety!

In addition to rigid devices, Broetje-Automation also offers the possibility of automatically assembling aircraft parts. Flexible tooling enables flexible and accurate installation thanks to the multi-positioning system. An implementation of this tool is available for a number of different machine types and can therefore be highly adapted to the needs of customers in aircraft production. It allows the loading and unloading of outer skin parts in horizontal and vertical orientation as well as continuous riveting without interruption for the repositioning of contour plates. With the help of vacuum cups and clamps, the components are held reliably and gently during the entire fastening process.

Jigs & Tools Product Information

Please download more technical details on our Jigs & Tools here.