- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

As a mechanical engineering company for automation solutions, we not only offer applications for the manufacturing process of components, but also mobile solutions for production-related transport and mobility concepts. Our portfolio ranges from AGVs in various sizes to entire automated transport systems for large components and solutions for individual applications. The different systems are customizable and can be tailored to all customer requirements.

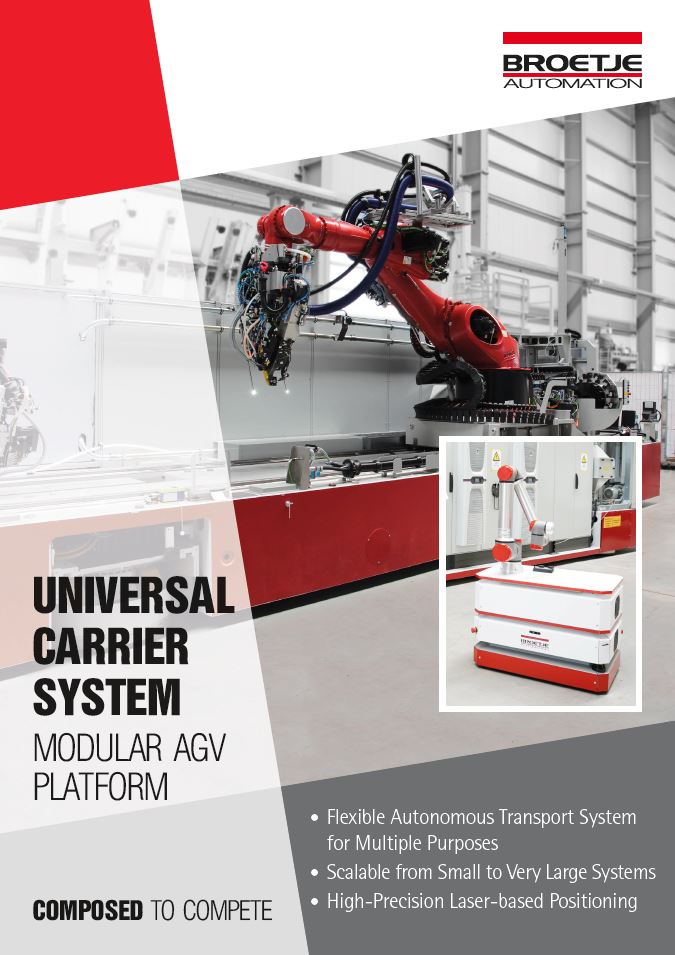

Universal Carrier System AGV

A mobile platform with different sizes and configuration options. This system can be used for machines and robotic systems to increase flexibility in the production hall. But not only automated machines can be placed on this system – it can also be used in the logistic field and transport components between assembly stations.

FastPlant Conveyor System

A system that brings the transportation of assembly parts to the next level. The loading and unloading process of different parts is made easier than ever before with this system. It increases the fast transport between the working stations with a flexible adaption to different material flow layouts.

Special Purpose Systems

To increase the flexibility you need for your individual, demanding project, Broetje-Automation is able to support your ideas and implement them with the help of our many years of experience in the field of automation.

Mobile Systems Product Information

Please download more technical details on our Mobile Systems here.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.