- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

As sustainability gains more importance, retrofitting existing machines is a cost-saving way to prolong the life-cycle of already installed production systems. Our team offers 10 years of knowledge in this field to advise our customers with the best outcome possible.

Retrofits are a sustainable solution to prolong the life cycle of outdated systems that would soon be replaced. With the retrofitting options from Broetje-Automation those machines can be kept in service much longer with an increase in productivity. Offering a sustainable solution that enables many opportunities.

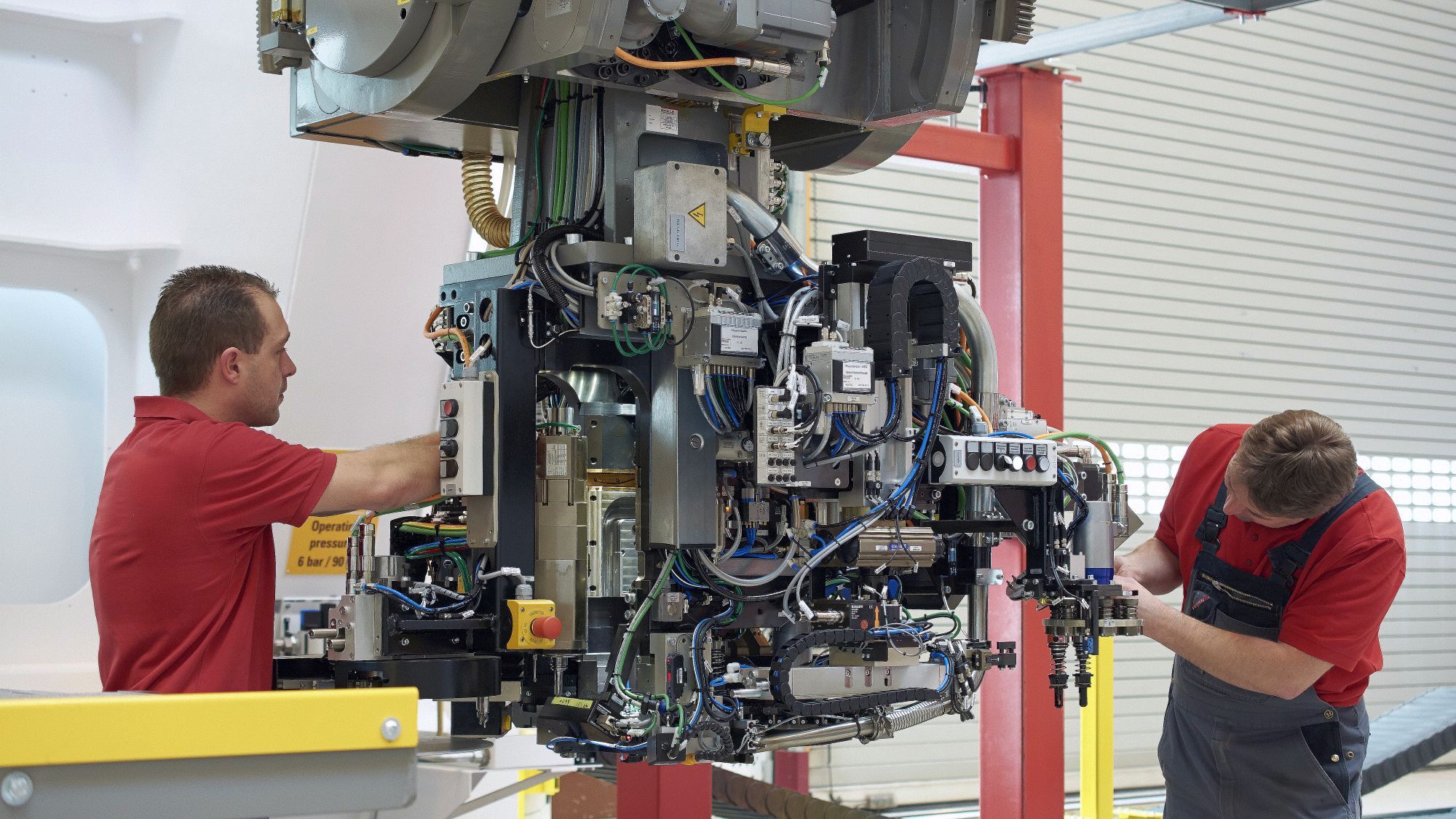

A modular design of the Broetje-Automation fastening lines allows for the latest state-of-the-art technology to be implemented, even after many years of operation. Modernization measures upgrade the riveting lines with the latest technology and evoke higher levels of automation and less machine downtime.

The increase in the degree of automation brings a significant change. The installation of tool change systems with a higher level of automation and a new digital NC control system ensures that the machine operator can run the system even more easily and intuitively. In addition, intelligent sensor-controlled monitoring and smart camera systems improve the quality of production and ensure even greater process reliability.

Sustainable opportunity for production systems

Retrofits provide a big lever to improve efficiency and reduce the carbon footprint of the production system at the same time. Retrofits have the advantage of providing similar production efficiency compared to a new system but save shopfloor time and reduce the carbon footprint by re-using parts of the system.

Besides the efficiency and productivity gains of the individual machines, retrofits expand the component spectrum, allowing manufacturers to edit larger components after the retrofit.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.

Aircraft Production goes “GREEN” – Broetje-Automation Collaborates with Airbus Aerostructures to Promote Sustainable and Resource-Efficient Production

- Published on 23 February 2024

- Company

- Factory of the Future

- Service

Broetje-Automation has successfully collaborated with a broad industry consortium to identify ways to reduce the environmental impact of today’s production facilities. The “GREEN” project, a joint initiative of a consortium of partners including OFFIS e.V., DLR e.V., ProIng and Broetje-Automation GmbH under the leadership of AIRBUS Aerostructures, developed measures to reduce the power consumption of old systems by up to 85% in certain areas of application. Overall, especially retrofitting older systems allows significant contributions towards a more sustainable industrial production.