- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

Digitalization and intelligent resource management lead to advanced factories. At Broetje-Automation, we are leading experts for large turnkey projects in the aerospace industry. That’s why we advise our customers from start to finish for a custom-fit solution tailored to their specifications.

The planning phase is the beginning of projects that often last many years. Together with our customers we evaluate their specifications, requirements and advise them with our knowledge to show even better result possibilities.

Control of production lines in conjunction with high-tech digital solutions offer the next big step towards greater efficiency, time savings and ease of management in production. The networked digital line management solutions provide a deep understanding of the overall process and reveal previously unimagined potential for improvement.

The Smart Factory contains advanced high-tech systems that enable intelligent and connected production, giving workers the tools to control more machines and increase production rates. Smooth, controlled, lean and efficient processes lead to the Factory of the Future.

Factory Planning

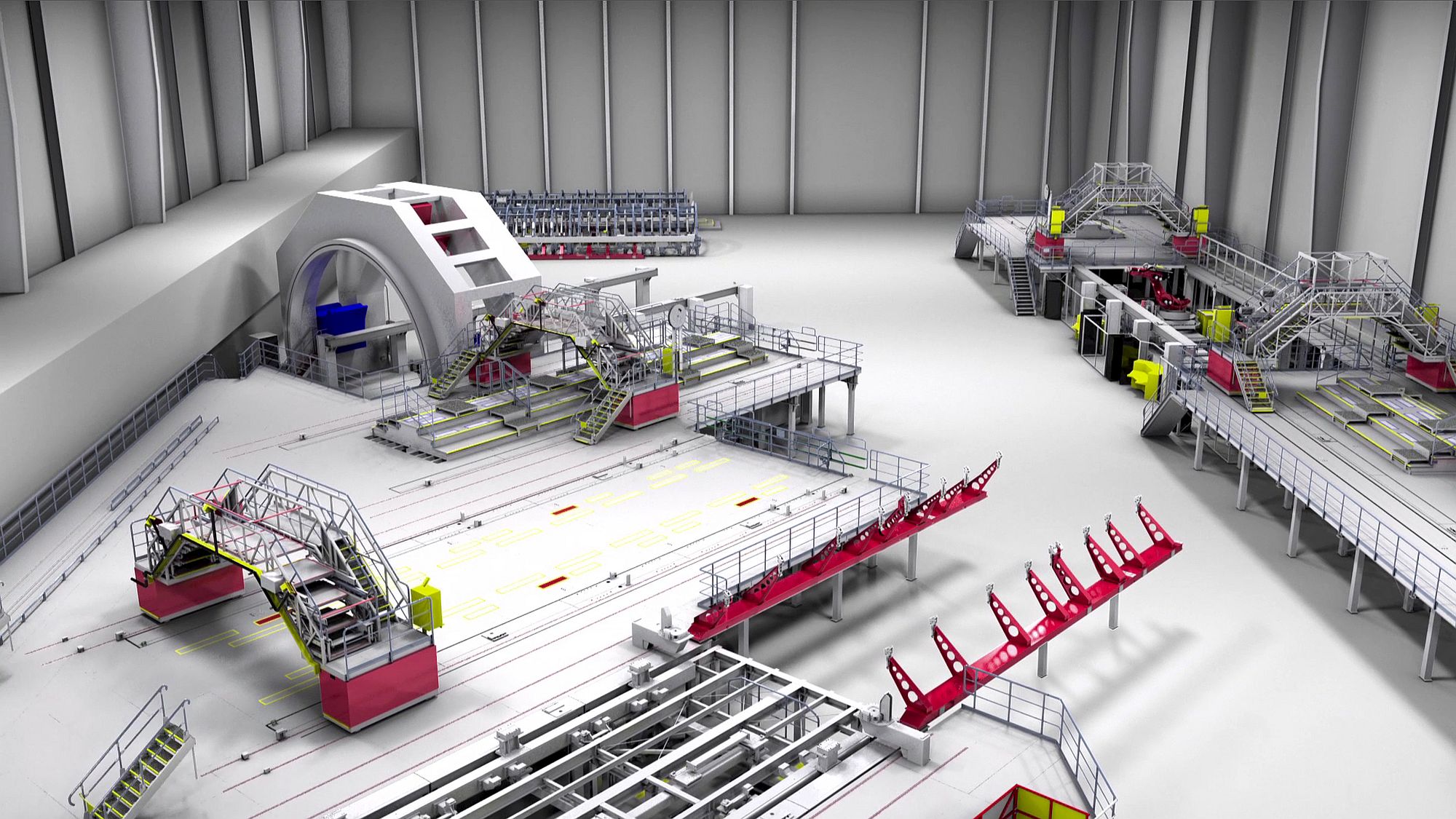

Tailor-made concepts ensure optimal utilization of hall capacities and individual planning of the shopfloor. A systematic planning approach from the first sketch to the complete factory layout in 3D ensures full satisfaction of the customer, who is closely involved in the development of the concept right from the start – Together we create the concept and implementation of the future and its high-tech solutions.

Project Implementation

To meet the challenges of implementing large-scale projects, Broetje-Automation focuses on teamwork, experience, digital tools, and a broad global network to deliver exceptional quality projects.

SOUL LMS

The line management system provided by Broetje-Automation offers tailored digital integration solutions for both new and existing production lines. The system allows the control and monitoring of the entire production line, which helps to improve speed and consistency.

Automated Isolation Gown Production

Broetje-Automation and STARK Medical have developed a fully automated integrated production system for non-woven fabrics to produce medical gowns locally. The system’s ability to also use recycled material provides a sustainable approach to disposables and reduces environmental impact.

INSIGHT INTO SMART PRODUCTION CONCEPTS

Solutions are as different as our customers. Gain more insight into factory solutions of the future.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.