- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

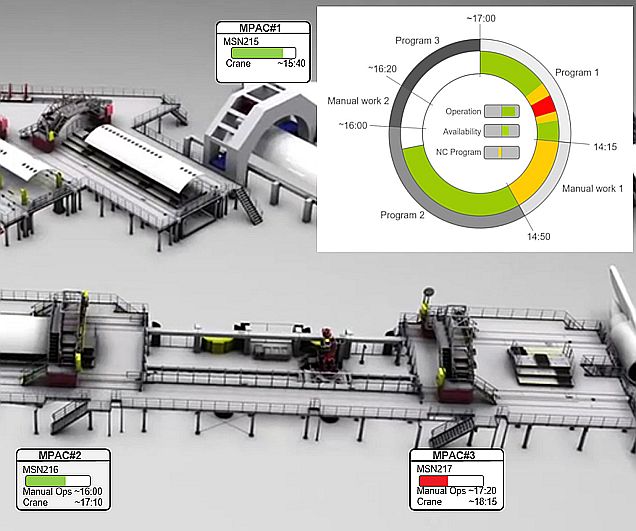

The line management system provided by Broetje-Automation offers tailored digital integration solutions for both new and existing production lines. The system allows the control and monitoring of the entire production line, which helps to improve speed and consistency. Integrated automated and manual process control provides application-specific flexibility within the customer environment.

Additionally, Broetje-Automation provides flexible integration options for customer MES and ERP systems. With these features, the line management system can provide increased connectivity and interlaced production, enabling businesses to streamline their operations and optimize their production processes with the help of digitalization.

Interconnectivity of various industrial applications

Integrating different industrial applications in one production line is a challenging task. At Broetje-Automation we enable higher quality, better production rates and good process tracking of the previously processed stations through our networked and integrated line management system. While the machines interact with each other and pass the structures to the next machine fully automatically, the system keeps track of the workpiece status. Thus, work packages can be taken over quickly in case of anomalies in production.

To ensure the protection of our customers’ shopfloor data, the advanced software solutions are hosted on mirrored databases.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.

Innovative Large Mobile Robot for Pioneering Research

- Published on 22 January 2024

- Assembly

- Digitalization

- Factory of the Future

- Mobile Systems

A Highly Flexible Industrial Robot System Opens New Possibilities for the Assembly of the Future at the WZL of the RWTH Aachen. Broetje-Automation delivered the large mobile robot system now to the WZL facility in Aachen, Germany.