- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

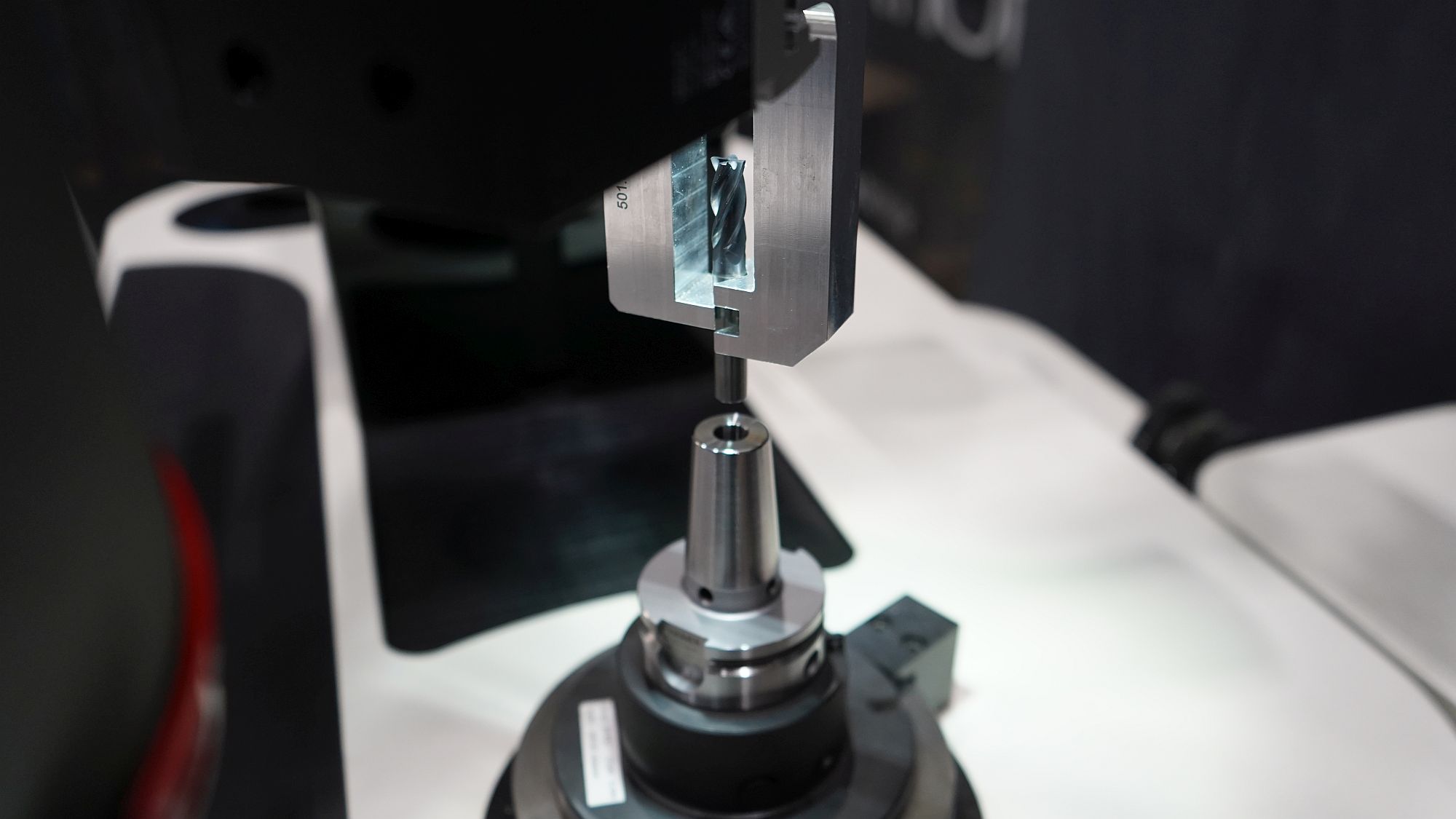

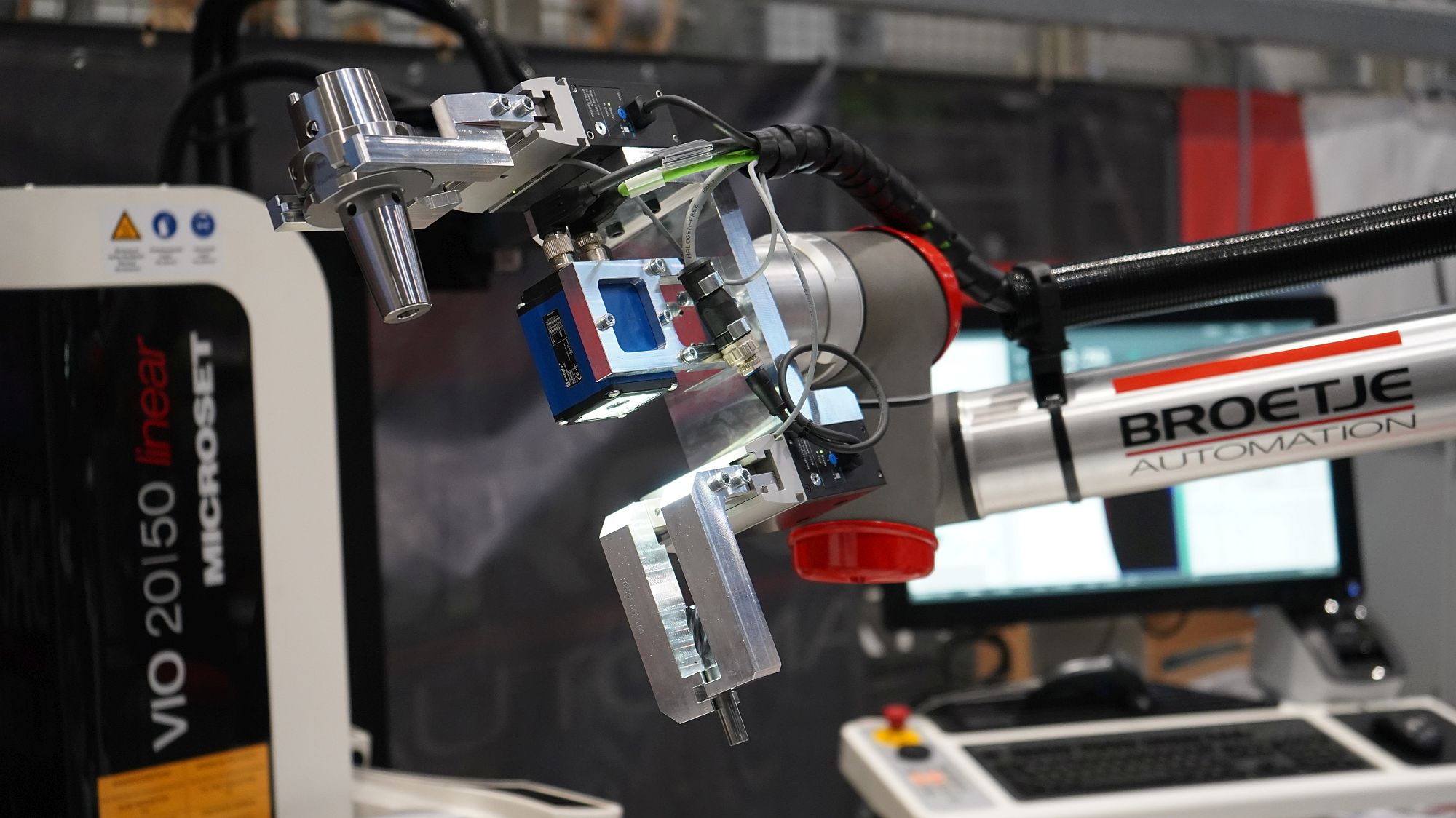

Broetje-Automation‘s Tool Management system automates supportive processes for machining applications. From tool provision, over tool set-up, tool measurement to management of tool storage the system ensures shift-independent operations of machining systems.

The system not only increases efficiency but also provides added value towards a safe, sustainable and resilient production. Based on a modular approach, the system can be adapted to individual requirements depending on production rate, workshop space requirements and level of automation.

Configuration Options

• Manual loading of the turntables, e.g. second shift

• Kick protection mat secures work area

• Worker can also use Station manually

• ~10 cycles per hour

• Robot performs tool handling

• Worker equips automated washing machine and tool storage

• tool accessibility via HSK wagon

• ~20 cycles per hour

• Double Robot Cell for tool handling

• Worker equips automated washing machine and tool storage

• Tool accessibility via automated tool storage

• ~40 cycles per hour

Automated Tool Management Product Information

Download our product flyer for more detailed information about the Automated Tool Management Solution.

More Impressions of the Automated Tool Management Solution

A modular solution for the automation of flexible and digitally integrated industrial applications. The system offers the freedom to create individual process applications through configurable modules tailored to specific customer requirements.

Tailored, Digital, Mobile, Sustainable – Successful Showcasing at 54th Paris Airshow

- Published on 13 July 2023

- Factory of the Future

- Mobile Systems

- Processes

The 54th Paris Airshow at the Le Bourget Exhibition Center from June 17-25, 2023 was a great success for the Broetje-Automation team. Broetje-Automation Group showcased its state-of-the-art automation solutions tailored specifically for the aerospace industry. One of the highlights was the latest innovation in robotic sealing application. The live performing collaborative robot caused many visitors to stop and take a look.

Robotic Sealing on the Rise – Broetje-Automation presents Versatile and Precise Options for Automated Sealing

- Published on 22 June 2023

- Factory of the Future

- Processes

With the introduction of robotic sealing for a wide range of components and Cobot sealing for increased flexibility, Broetje-Automation presents high-tech sealing processes for the aerospace industry. These advanced automation solutions reduce process steps, labor hours, and costs, while ensuring reliable high-quality sealing and waste reduction, resulting in improved efficiency and productivity.