- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

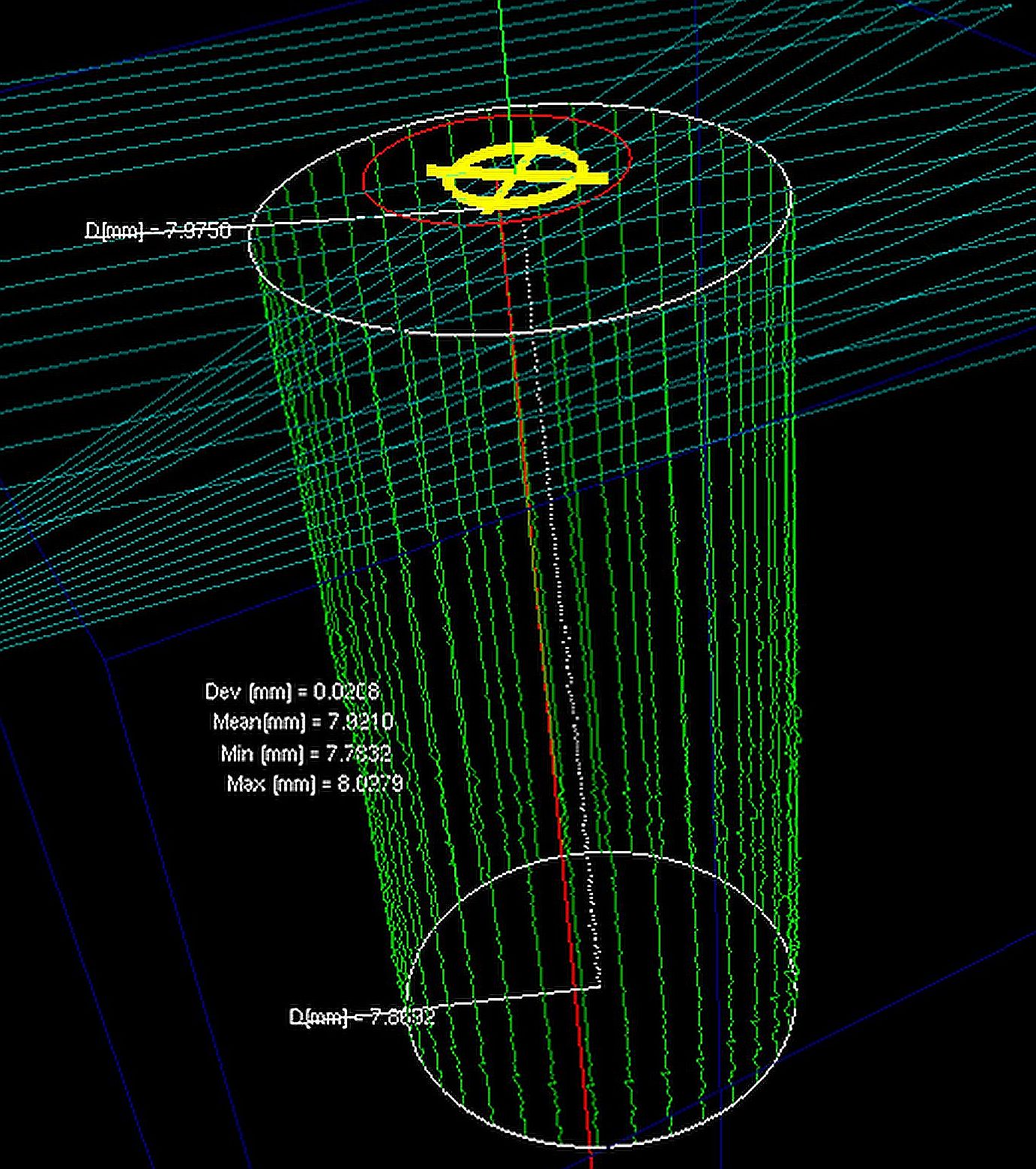

Precision is one of our many qualities. To optimize tolerances in the factory of the future, we use drill hole measurement technology for our fastening systems. This improves the drill hole quality and prevents incorrect positioning. The drill hole and countersink parameters are measured with a dual camera system which provide reliable results even when there is dust on the surface. To achieve this, Broetje-Automation provides eight measurement tools depending on the customers needs that provide a complete range of drill hole measurement data and prevent unreliable test results as far as possible. The selection of measurement methods include hole probe measurement, chip detection open hole, drill hole diameter measurement, countersink diameter measurement, color detection, position sensor, dual position sensor and a normality sensor. With an overall process accuracy of 0.025mm/0.001″ for the drill hole measurement it increases the quality of the structure immensly.

Measuring Modules

- Position Sensor/ Dual PSen

- Normality Sensor (NSen)

- Color Detection (CODT)

- Countersink Diameter Measurement System (CDMS)

- Drill Hole Diameter Measurement System (DDMS)

- Chip Detection Open Hole (CDOH)

- Hole Probe Measurement (HPMS)

- Fastener Measurement System (FRMS)

- Sealant Check Open Hole (SCOH)

- Sealant Check Close Hole (SCCH)

- Edge Trace Monitoring System (ETMS)

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

VE2E: Research project for the development of the factory of the future a complete success

- Published on 11 March 2024

- Allgemein

- Assembly

- Digitalization

- Events

- Factory of the Future

- Service

It began as a promising vision in July 2021 and has now come to a successful conclusion: the research project “Vertically integrated, sustainable end-to-end factory (VE2E)” for the development of a digital Factory of the Future. At the beginning of March, the forward-looking results of the research project were presented to a wide audience at Premium AEROTEC’s Varel site.