- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

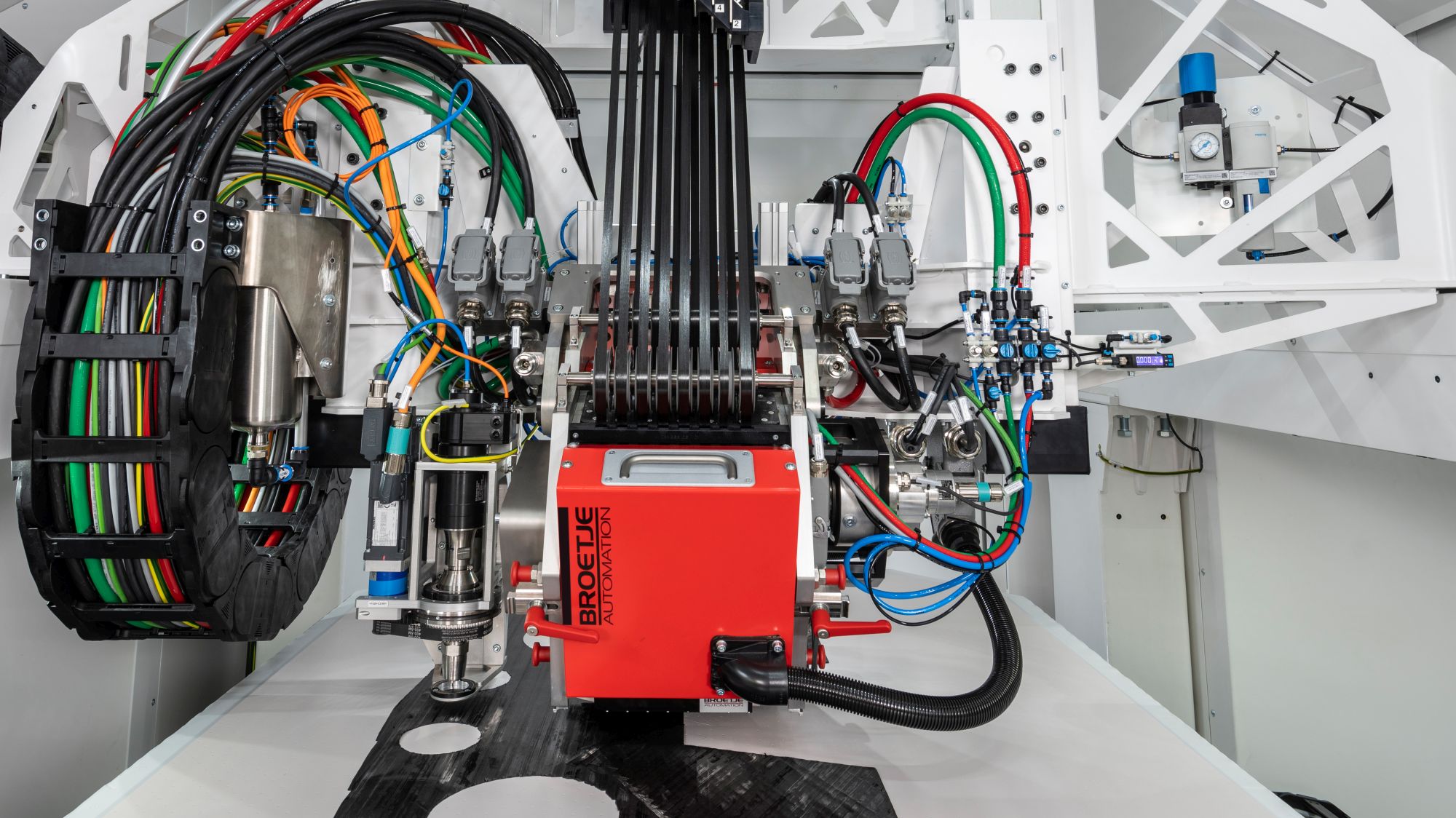

The STAXX COMPACT is robust standalone 16-lane fiber placement machine designed for high volume industrial production. The system is ideally suited for the mass production of small composite parts. It achieves high workpiece quality while minimizing material waste.

It comes with Broetje-Automation´s HMI (Human Machine Interface) SCORE coupled with an automated workpiece loading and unloading system as well as intelligent quality control results in reduced workload, thus decreasing labour cost and cycle times.

The machine allows for integration into a flowline concept connecting multiple stations in order to automate and accelerate the manufacturing process even further.

Technical Data

- Material flexibility: 16 tow Towpreg, Prepreg and Dryfibre 1/4‘‘ (6,25mm) or 1/2‘‘ (12,7 mm)

- Feed rate 60m/min

- Cut on the fly 45m/min

- Max. part length: 66,92‘‘ (1700mm)

- Pallet size: 1525mm x 900mm

- 4-axis layup (x,y,z,c)Z-travel: 500mm

- Electrical Installation: 30kW

- Pneumatic Installation: 6bar

- Air conditioned enclosure including creel and material storage

- Double-sided parallel loading / unloading with zero point clamping systems

- Pallet handling system

- Ultra-compact machine design: 6500mm x 3000mm x 3000mm

- Siemens 840D-SL Controls

Special Features

- Direct layup of 2D unidirectional carbon fiber net shape

- Totally enclosed and air conditioned system for maximum flexibility

- No limitations in fiber orientation

- Automated component loading and unloading

- Closed air conditioned cell resulting in high safety and high scalability

- Easy material reloading

- Operator friendly Human machine interface

- Compact dimensions, easy relocation

By loading the video, you agree to YouTube's privacy policy.

Learn more

STAXX Compact Product Information

Download our product flyer for more detailed information about the STAXX Compact.

The Future of Wind Turbine Production – Broetje-Automation showcases automates solutions at the IPF Offshort Partnering Forum in New Orleans

- Published on 26 April 2024

- Assembly

- Company

- Factory of the Future

- Fastening

Latest developments for the offshore wind energy and green hydrogen sector were discussed at the IPF Offshore Partnering Forum from April 23 – 25 in New Orleans. Under the umbrella of the German Wind Industry and Hydrogen Association WAB e.V. Broetje-Automation showcased innovative solutions for the factory of future for wind turbine production.

Represented by the Federal Ministry of Economics and Climate Protection in cooperation with the Trade Fair Committee of German Business the German Pavillon brought together a broad spectrum of competences from many companies along the entire wind energy value chain. “Stronger together” was the leading WAB motto and program for three days of networking!

Cooperation between the Emden/Leer University of Applied Sciences, the Economic Development Department of the City of Emden and Broetje-Automation: regional strengthening through collaboration.

Broetje-Automation, the City of Emden’s Economic Development Agency and Emden/Leer University of Applied Sciences are embarking on a cooperative path from 22.04.2024 to develop and implement innovative solutions to future challenges in the field of sustainability. This will be driven by the “Sustainable Product Development in Mechanical Engineering” course, which has been offered at Emden/Leer University of Applied Sciences since last year.