- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

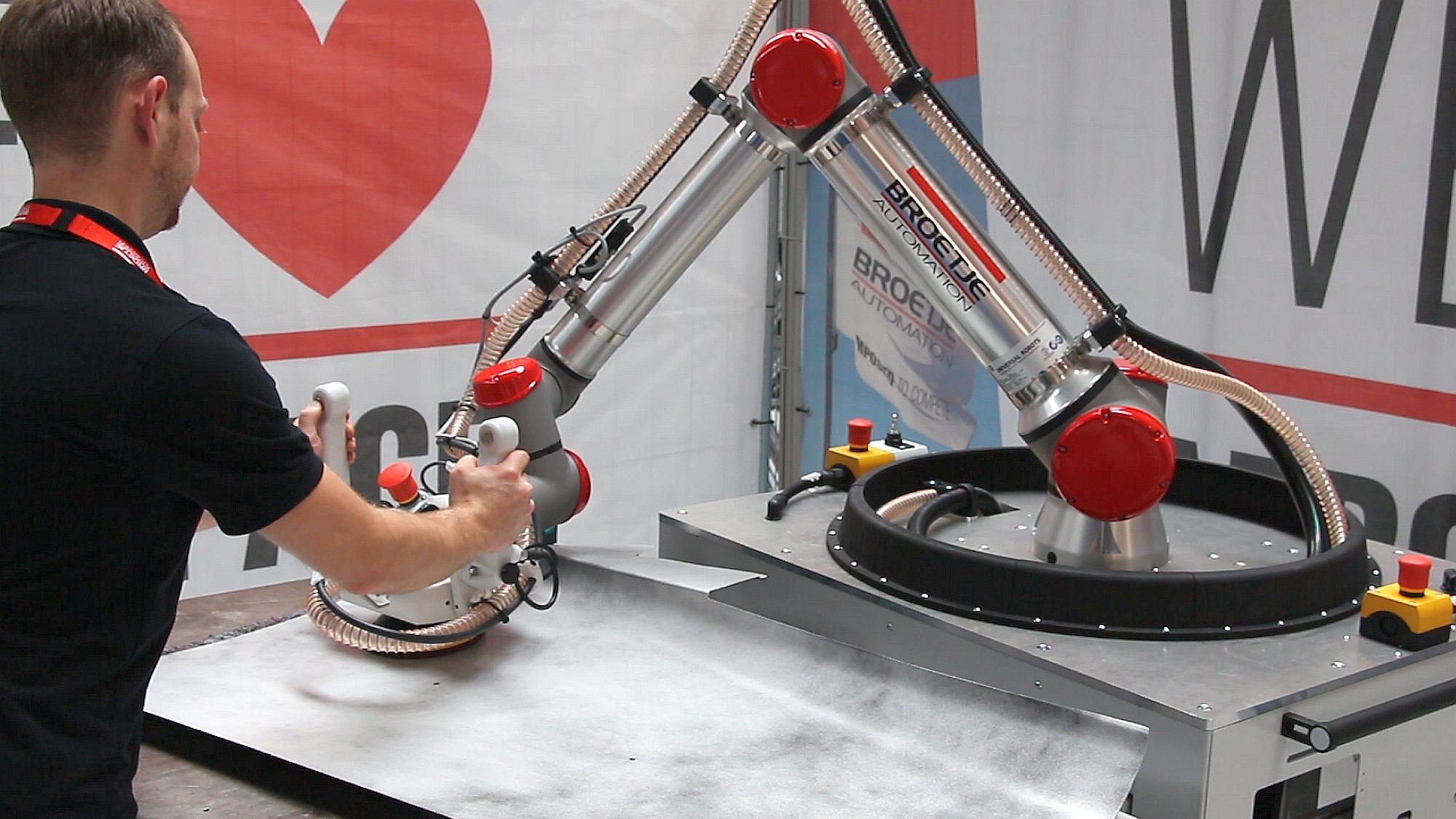

The Sanding Cobot system provides mobile, semi-automatic surface sanding. The system leverages Broetje‘s modular toolbox for lightweight collaborative robotics and combines the industry-proven UR10e positioning system with an interchangeable, custom-built end effector that uses a Mirka sanding head. No programming is required thanks to the robot‘s automatic path generation. The system is mounted on a mobile rolling base and can be operated by the worker without lengthy training. This allows the system to be used from lot size 1. The Sanding Cobot system is capable of roughening surfaces of all types in preparation for painting in various industries such as aerospace, shipbuilding, automotive and wind turbine manufacturing. The safety system enables applications in a collaborative environment with humans.

Technical Data

Sanding End-Effector

- Rotating Speed: 4000-10000 rpm Grinding disc diameter: 77 / 125 / 150 mm

- Standard sanding speed: 15 mm/s Sander by Mirka

- Pressure force: 30 – 90 N Gimbal for automatic adaption to surface Fully adjustable handles

Robotic Arm

- Universal Robots UR10e off the shelf with Orbit: 5 mm (excentric) URCap Finishing CoPilot

- Reachability: 1300 mm

- 6 Axis

- Weight: approx. 35 kg, Payload: 10 kg

- Reachability: 270° on both working sides

- Vacuum / Power supply (230V) from the top

Special Features

Full process integration by Broetje-Automation

- State-of-the-art safety systems including CE conformance in compliance with ISO TS 15066

- Force controlled robot movement

- Automatic adaption to surface

- Ideal surface contact thanks to integrated Gimbal

- No programming required

- Ergonomic working

- 2 Presets for Sanding and Polishing

- Adjustable handles

- Entire process can be controlled at the endeffector: handguiding, teach-in, start/stop, presets

- Automatic path creation

- Optional: autonomous guided vehicle platform (AGV)

By loading the video, you agree to YouTube's privacy policy.

Learn more

Tailored, Digital, Mobile, Sustainable – Successful Showcasing at 54th Paris Airshow

- Published on 13 July 2023

- Factory of the Future

- Mobile Systems

- Processes

The 54th Paris Airshow at the Le Bourget Exhibition Center from June 17-25, 2023 was a great success for the Broetje-Automation team. Broetje-Automation Group showcased its state-of-the-art automation solutions tailored specifically for the aerospace industry. One of the highlights was the latest innovation in robotic sealing application. The live performing collaborative robot caused many visitors to stop and take a look.

Robotic Sealing on the Rise – Broetje-Automation presents Versatile and Precise Options for Automated Sealing

- Published on 22 June 2023

- Factory of the Future

- Processes

With the introduction of robotic sealing for a wide range of components and Cobot sealing for increased flexibility, Broetje-Automation presents high-tech sealing processes for the aerospace industry. These advanced automation solutions reduce process steps, labor hours, and costs, while ensuring reliable high-quality sealing and waste reduction, resulting in improved efficiency and productivity.