- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

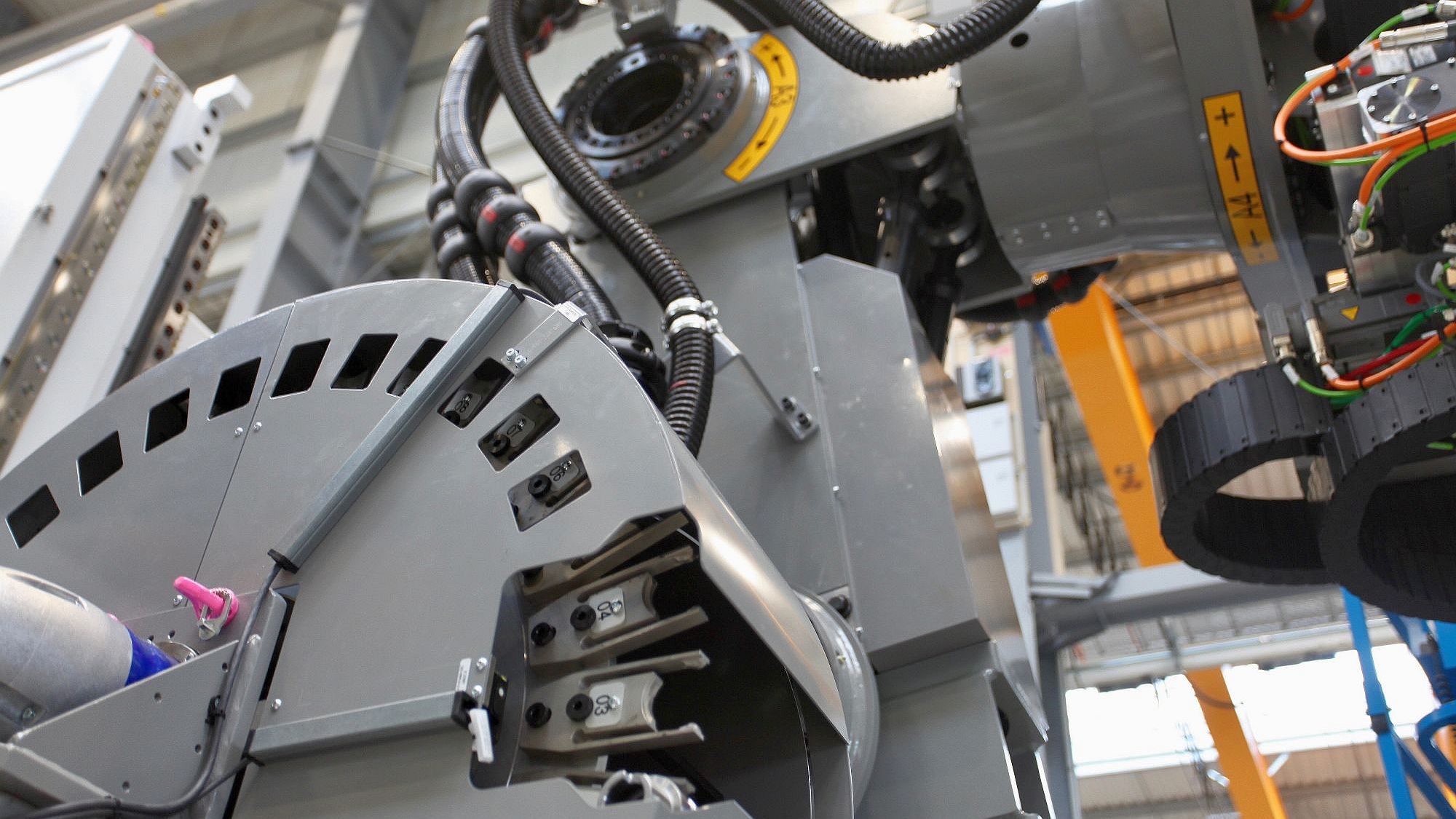

The Power RACe (Robot Assembly Cell) is a highly flexible robotic system specifically designed for the needs of the aerospace industry. It functions as an automated positioning system to perform multiple processes in one machine such as drilling, riveting, milling and other high precision, high-force applications.

Components such as wing box, stabilizers, fuselage etc. can be automated drilled and riveted by the mobile robot. The system is highly standardized and relies on proven technologies with long term spare part availability. With up to 50% reduced drill times and 40% higher overall performance, the Power RACe is the ideal system to automate complex industrial manufacturing processes – suitable even for lower rate programs.

By loading the video, you agree to YouTube's privacy policy.

Learn more

Technical Data

Drill end-effector

- Drill speed: max. 24.000 rpm

- Drill spindle feed: up to 197 “/min / 5.000 mm/min

- Drill diameter: up to 5/8” / 15,90 mm

- Countersink repeatability: ± 0,0006”/ ± 0,015 mm

- Clamping force: 110 – 600 lbs / 50 – 270 daN

- Hole quality : up to H7

Positioning system

- Positioning accuracy linear axis: ±0,004“/ ±0,1 mm

- Positioning accuracy 3D: ±0,012” / ±0,3 mm

- Positioning repeatability 3D: ISO9283 Value ±0,002” / ±0,06mm

- Work envelope : 4m x 5m x 1,5m

- Double bearing and master slave drive trains for highest stiffness and minimum backlash

Special Features

- Standardized drive train and controls

- Higher stiffness based on optimized machine design

- Maximum flexibility, no limitation to only one workpiece or workplace

- High speed precision drill spindle and tool changer (up to 30 places)

- Optional Movable platform with self-driven omni-directional wheels, stationary design or rail system

- Integrated automatic lifting, test piece holder and sensor calibration function

- Sensor Systems for Distance, Normality, Workpiece Zero Point, Tack Rivet Detection, Countersink Depth, Fastener Head Height, Hole Diameter, Sealant

- Observation of cartesian safety zones

- Closed loop position control with direct measurement systems

- BA Lube advanced lubrication system

- Vibration Drilling

Power RACe Product Information

Want to know more about our product? Click the Button below to download this document.

Ramping Up Wind Turbine Production with Torque Systems – Broetje-Automation delivers automated equipment to Siemens Gamesa

- Published on 21 March 2024

- Factory of the Future

- Fastening

The production of wind turbines is expected to increase drastically in the coming years. To prepare for a fast and reliable production ramp-up, Broetje-Automation supports Siemens Gamesa with automated equipment. With the delivery of an automated bolt fastening machine to the factory in Cuxhaven, the partners have reached an important milestone in the establishment of the Torque Systems product family.

Steady Winds are Rising – Broetje-Automation shows innovative approaches for the industrialization of turbine production

- Published on 12 September 2023

- Factory of the Future

- Fastening

Broetje-Automation has consistently pushed the boundaries of automation technology, delivering state-of-the-art solutions that enhance productivity, efficiency, and safety. Nowadays this knowledge is used in wind turbine manufacturing and assembly processes. With a commitment to sustainability and a focus on customer-centricity, the company’s presence at the Husum Wind Expo from September 12 to 15 is set to showcase its latest advancements and engage with industry stakeholders.