- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

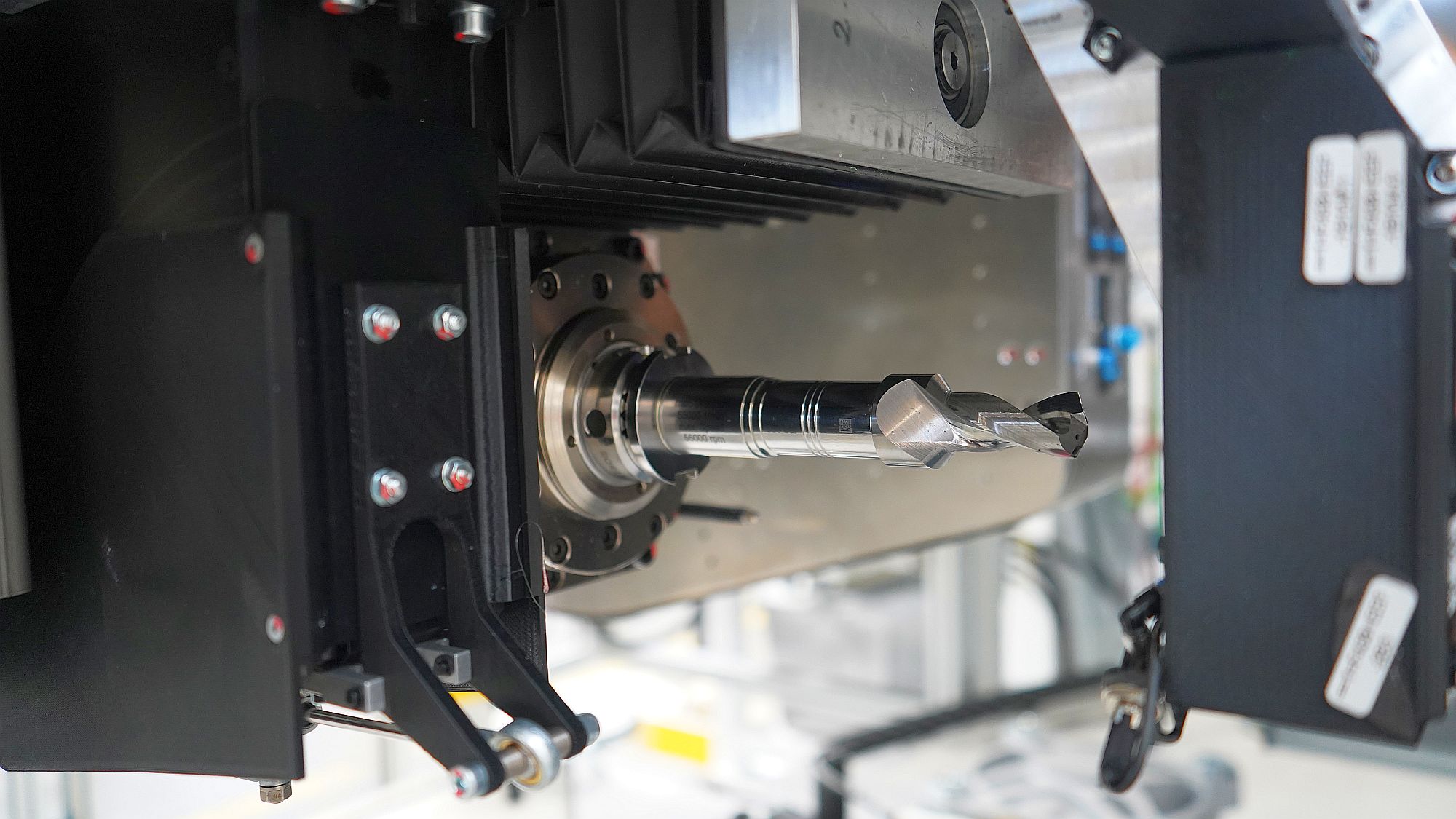

When working with lubrication-assisted drilling and milling, we have found that the process still has room for improvement. Therefore, we have developed our own lubrication system for these processes, which not only keeps the components oil-free, but also achieves better process quality, has shorter process times, extends tool life and ensures high reliability. With internal lubrication even for tools with small diameter cooling channels and optional upgrades for external lubrication, various materials such as CFRP and titanium can be precisely finished. With this technology, we minimize process times by up to 30% while doubling the number of holes during the drilling process. With aerosol dry lubrication, we also achieve a 20% reduction in drill wear for an even more efficient factory of the future and smart and efficient processes.

Tailored, Digital, Mobile, Sustainable – Successful Showcasing at 54th Paris Airshow

- Published on 13 July 2023

- Factory of the Future

- Mobile Systems

- Processes

The 54th Paris Airshow at the Le Bourget Exhibition Center from June 17-25, 2023 was a great success for the Broetje-Automation team. Broetje-Automation Group showcased its state-of-the-art automation solutions tailored specifically for the aerospace industry. One of the highlights was the latest innovation in robotic sealing application. The live performing collaborative robot caused many visitors to stop and take a look.

Robotic Sealing on the Rise – Broetje-Automation presents Versatile and Precise Options for Automated Sealing

- Published on 22 June 2023

- Factory of the Future

- Processes

With the introduction of robotic sealing for a wide range of components and Cobot sealing for increased flexibility, Broetje-Automation presents high-tech sealing processes for the aerospace industry. These advanced automation solutions reduce process steps, labor hours, and costs, while ensuring reliable high-quality sealing and waste reduction, resulting in improved efficiency and productivity.