- Industries

- Factory of the Future

- Products

- Company

- Career

- Contact

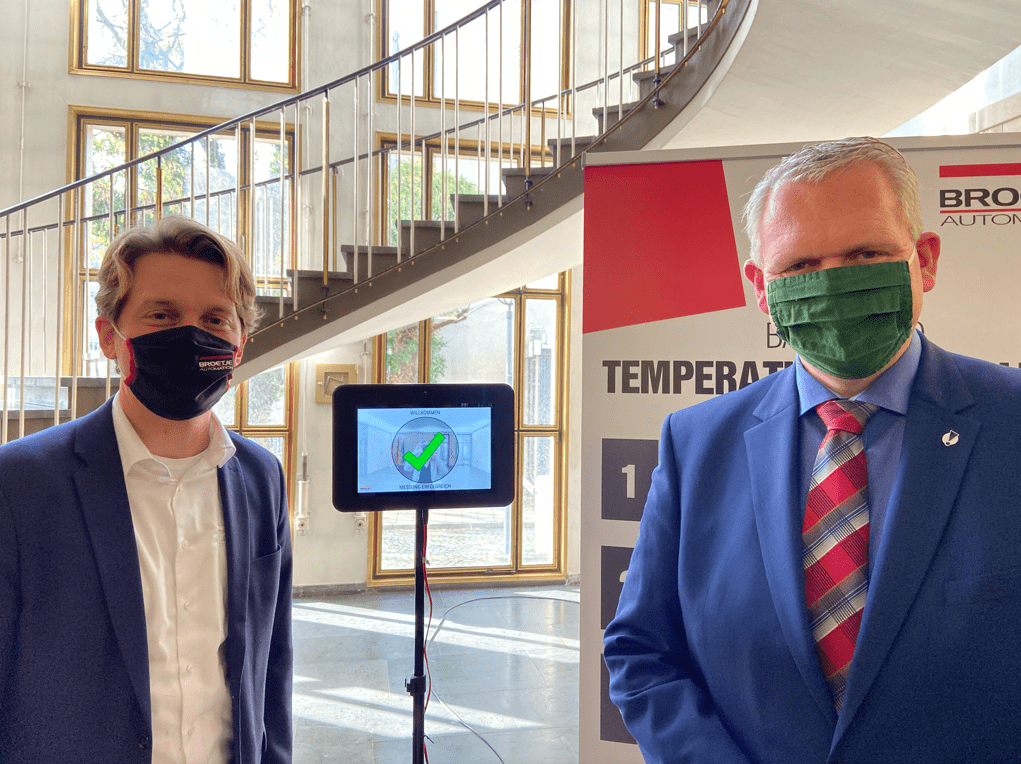

Comprehensive hygiene and protective measures have found their way into almost all major institutions in the course of the Corona crisis. The Ministry of Science and Culture of Lower Saxony now relies on a temperature scanner. In the ministry’s main building, Science Minister Thümler has now started the test phase for the use of BA Thermo, the temperature detector developed by Broetje-Automation in Lower Saxony.

Broetje Automation Thermo - Automatic Temperature Detector

In the fight against the corona pandemic, companies as well as public institutions must break new ground. But besides the many restrictions of public life, this also releases new creativity. In just a few weeks, Broetje-Automation developed a temperature detector at its headquarters in Rastede in the course of the first lockdown in March. Since then, the company has used the detector as an additional daily protection for its employees.

The solution was not only well received within the company, but also by customers, regional partners and many guests with great interest. As a result, Broetje-Automation decided at short notice to develop a market-ready product from the internal prototype project. Only a few months have passed since then and already a good dozen of the devices are in use at various customers throughout Germany.

Deployment at the Ministry of Science and Culture of Lower Saxony

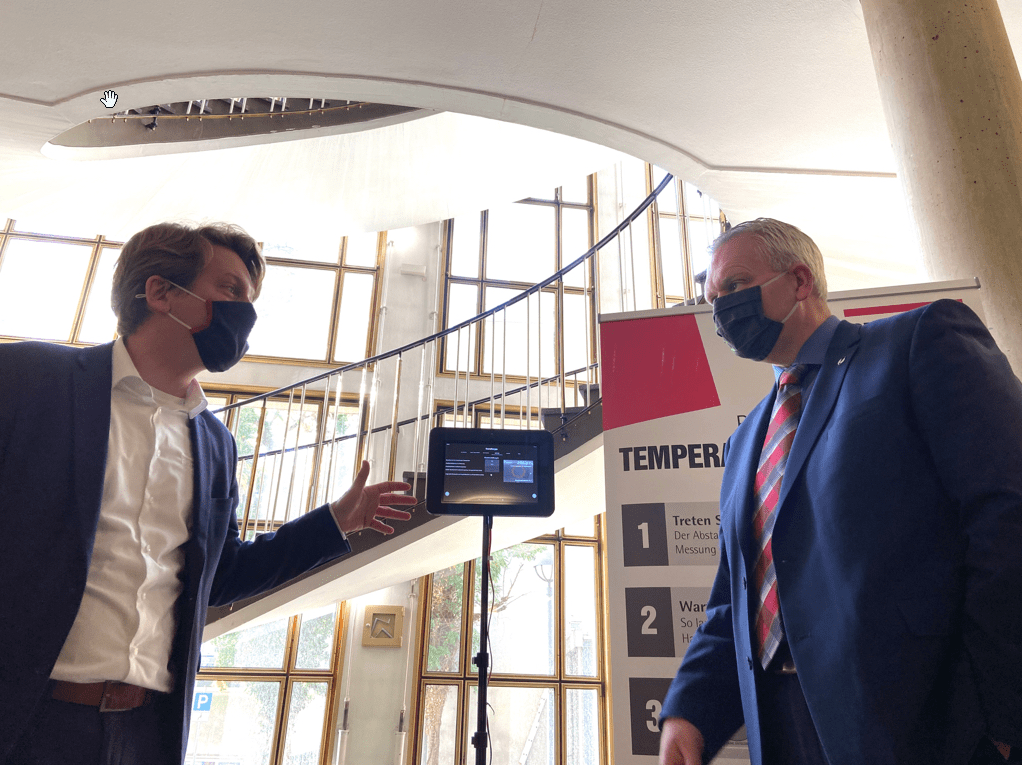

Now the device is being tested for the first time in a public environment. Björn Thümler, Minister for Science and Culture of Lower Saxony, accepted a test device of the BA Thermo system in the main building of the ministry in Hanover. “The Corona pandemic demands a lot from all of us. The best possible protection of my employees but also of our visitors is close to my heart. We are therefore constantly working on improving our hygiene concepts,” says Thümler.

The ministry has initially decided on a test phase lasting several weeks in order to gain experience with temperature measurement when entering the building. “So far, the measure has been positively received,” adds the Minister. “It is particularly important with such a temperature scan that personal data is handled responsibly”. BA Thermo does not store any data at all and leaves it up to the individual user to handle the result on his own responsibility. The system is thus fully compliant with data protection and complies with German data protection standards.

“We are naturally very pleased with the interest shown in our solution,” explains Norbert Steinkemper, Head of Communication and Marketing at Broetje-Automation. “For our team it was a completely new experience to develop such a product for series production in the shortest possible time”. Broetje-Automation produces highly complex automation solutions, machines and systems for the global aerospace industry. “We are particularly proud to have mastered this challenge in an extremely short time – and the positive feedback from our customers proves us right”, adds Steinkemper.

With BA Thermo, Broetje-Automation is not only breaking new technological ground, but also expanding its customer base. The system is used in very different industries and application areas where hygiene and health maintenance are of particular importance or, for example, large numbers of people have to be tested in a short time (e.g. for shift changes in industrial plants). The cultural and event industry as well as public institutions have already shown interest in using the system in order to be able to hold attendance events again as soon as possible.